|

|

Post by scooter on Oct 27, 2014 23:30:03 GMT -5

Using vacuum and fuel pressure gauges to take the guesswork out of diagnosing engine trouble. We've been discussing common issues on here like vacuum leaks, fuel cutout and so on, and I think it makes sense to use gauges to get data about what's really going on in our engines when these problems occur. I'm getting a vacuum and pressure gauge. I want to know if I have enough vacuum and what my vacuum pressure is at different RPMs, and how well my fuel pump is working at various RPMs. I might even plug up all of my vacuum lines and do a leak test to see if that's a problem. I'm hoping this will lead to a better knowledge of my engine and how it works. I've even read that you can diagnose valve setting and timing issues with this tool. What about you? Have you used these gauges? How useful are or were they to you? What kind of things did you use them to diagnose? Also here is a post about some gauges I found online if you're interested. Feel free to add to it. itistheride.boards.net/thread/6944/good-vacuum-pressure-gauge-testingHere is a video of a guy using a gauge just like the one I bought, and it sounds like he's reading the manual that comes with it. Interesting stuff. |

|

|

|

Post by scooter on Oct 27, 2014 23:14:35 GMT -5

I have been reading some posts here about fuel pumps, fuel pressure, and vacuum. It seems to me that a smart mechanic would want to know what's going on in their motor, and not just guess, so I'm getting myself a vacuum and fuel pressure gauge. I realize these are one cylinder engines, and that the use of these gauges may be limited for us, but I'd like to know things like, when the engine bogs out at wot, what is the vacuum pressure and what is the fuel pressure at the time? Also, some reading indicates that a vacuum tester may be able to tell me about my valves. It seems like a useful tool. I wrote this because I passed up a good deal. I bit the bullet and bought this unit for $20 because it's new, has a huge 3-1/2" dial, and a case to keep it clean and safe: cgi.ebay.com/ebaymotors/FUEL-PUMP-VACUUM-TESTER-Carburetor-Valve-Pressure-Tester-Gauge-Kit-Car-Truck-/330908988367But if someone needs one of these, this one, albeit used, is made in the USA and is only $8 with shipping and you'll have it in about a week or so: www.ebay.com/itm/Engine-Vacuum-Gauge-with-Hose-Made-in-USA/201201885181Here's another one Harbor Freight for only $15: www.harborfreight.com/fuel-pump-and-vacuum-tester-93547.htmlI don't know how much they sell for at walmart or your local parts store, but these seem like good prices to me. |

|

|

|

Post by scooter on Oct 27, 2014 1:46:32 GMT -5

Oh. It looks like a few ounces of weight loss, not pounds.

|

|

|

|

Post by scooter on Oct 27, 2014 1:30:28 GMT -5

Ally makes a good point in suggesting we remount our fuel pumps lower than the tank. It's def worth trying. On my scooter that would actually take some doing. I would have to fabricate some sort of custom mount. I'm only at 155 CCs. A good portion of the power I'm producing comes from the A11 cam..seriously this cam opens the valves up almost to their max tolerances. Then having the head ported and polished further helps shovel the go juice through the motor. With the stock jets (125M/40P) on a 30mm carb I was running really lean on initial tuning and testing. Yes, that does sound like a good idea. Mine is about even with the bottom of the tank. I may have to get me one of them fancy cams. Makes the bike sound good too. |

|

|

|

Post by scooter on Oct 27, 2014 1:22:49 GMT -5

Exactly why in your variator mod thread, why I said how dangerous it could be to go messing with these things. That was his choice. I think he called it overranging or something like that. I would not run mine like that. Every time I put my cvt together I rev it up and see how high the belt goes. Sounds like the people making the variator you want are making a lot of cuts and chops on theirs. I suppose they have done their homework and testing. I know I would before selling something like that. Sounds nice, especially the three pound drop in clutch weight. |

|

|

|

Post by scooter on Oct 26, 2014 22:54:46 GMT -5

scooter My original setup was just like yours and had the problem. It sounds like you need a more efficient pump or, like you are saying, a different kind of pump altogether. Have you had this problem since the scooter was new? Your scooter sounds really powerful. How many cc's are you at now with that BBK? |

|

|

|

Post by scooter on Oct 26, 2014 21:45:43 GMT -5

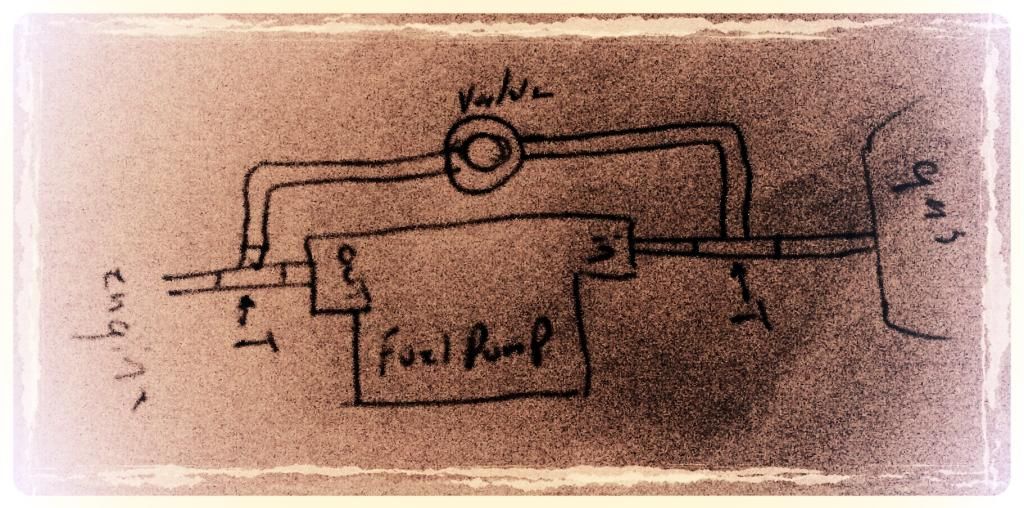

scooter I'm thinking the same thing. Just we have two factors to worry about, 1 the pump not providing enough fuel, 2 The pump pushing too much fuel. The second is actually the easiest to deal with. A simple in-line fuel regulator should solve the problem. But until one of use attempts this upgrade wee just don't know what's going to happen. At 20-30 gph the pump rcq92130 linked should be more than sufficient. rcq92130 I never really trust stats on anything I buy from the bay. They are often either inflated or reduced, depending on what makes said product look better to the consumer. If I were you I would test the new pump prior to installation. Get a bucket and an empty gallon milk jug and see how long it takes the pump to fill the jug. Then calculate the pumps actual gallon per hour rating. Oh, man, 20-30 gph. I'd bet 2gph would be more than enough. Yes, like rcq, I'd be concerned the pump would overpower the needle valve. I have no idea how much pressure they could take before being forced open. I don't know how a regulator works but I suppose one could run a fuel return line back to the tank with an adjustable valve or a restriction in it to let off and adjust pressure. You might even be able to run the return hose to a Y on the pump's intake side, although I suppose having the fuel recirculate in such a short loop might build up a little heat, but it sounds negligible. If I were only testing, I might skip the valve and run the line to the tank vent with or without some restriction in it.  I just thought of something while I was talking to gregory. It occurred to me that one change I did make, while rehoseing (is that a word? if not I call it!) my vacuum system, was that I put the fuel pump on one of the intake nipples by itself. I have two. The canisters are on one line with y connectors, and the fuel pump is by itself on the other side. It seemed to me that something as important as the fuel pump should not be sharing leaks and pressure variations with other components. Who knows if that made any difference. So that's 3 things I changed leading to what is now a good working engine. Tightened the intake manifold. Cleaned the fuel pump. Put in new vacuum lines. Put the fuel pump on an intake vacuum nipple by itself. |

|

|

|

Post by scooter on Oct 26, 2014 21:35:54 GMT -5

I just purchased a 150cc Chinese scooter. I've had several others so I'm somewhat familiar with GY6 operation and maintenance. Scooter was not running. Original owner started having problems after replacing hoses. As I suspected he had vacuum leaks all over b/c new hoses were not snug. Does canister 1 look like this:  If so, it's probably a fuel filter. Next: The valve cover has a line to let out pressure to the air box Next: Each canister that works on a vacuum should have three or more hoses. The fuel pump or petcock has fuel in fuel out vacuum line to run the pump. If you have the big hose going from the valve cover to a canister and then to the air intake tube or box then it should also have 1 vacuum line to it, to operate it. so that's valve cover big hose to canister big hose from canister to air intake or air box a vacuum line to operate it other holes are vents you may also have a vapor recovery canister from the top of the gas tank line from top of tank to a canister line from canister to air box, i think and a vacuum line to operate the canister like you, I have two intake nipples for vacuum lines. i hooked up one side to the fuel pump only. i hooked up the other side to the other canisters with "y"s or "t"s. |

|

|

|

Post by scooter on Oct 26, 2014 18:53:26 GMT -5

As for "scooter's" comment: My vacuum operated P.O.S. pump failed after 3 months. THAT is a source of failure. In fact - the entire notion of bleeding off manifold vacuum seems stupid to me, as is the idea these vacuum pumps will necessarily do all that is needed, reliably, at WOT. Electric is fine in those situations, and - if you ever have to empty the carb bowl of fuel, you will not be cranking for a day to get the engine to first start. I am beginning to understand the vacuum system a little better. Seems opening the throttle plate produces a giant hole in our engine's "vacuum box", so when we are at WOT, the "leak" is at its worst, and right at the time when need the most fuel. This would also suggest that using a carb that is too big will create vacuum issues. I suppose using an external vacuum pump for the fuel pump would be one way to fix it, but an electric pump sounds like an easy and simple alternative. dmartin95 rcq92130 alleyoop xyshannen |

|

|

|

Post by scooter on Oct 26, 2014 17:21:31 GMT -5

The variators are built to not allow the belt to get to the edge for safety so that the belt does not have a chance to pop off. The belts you will find will travel no higher than approx 1/8 from the edge on any given variator. So if you can get your belt to climb within 1/8 of the variator edge you cannot get any better than that. Alleyoop That's good to know. It seems obvious that if the belt is 20mm wide then the smallest width the variator should have when the pulleys are together is 20mm at the top. I saw a video the other day where a guy's belt was riding halfway out of the variator but I think he had modified his pulley with a file if I'm not mistaken about which video it was. |

|

|

|

Post by scooter on Oct 26, 2014 17:10:00 GMT -5

since I am running a 150cc, I won't leave my numbers but I did set my variator using my engine's listed max torque rpm and max hp rpm as targets.

|

|

|

|

Post by scooter on Oct 26, 2014 16:58:42 GMT -5

I just bought my first set of sliders. They pushed my belt up higher even though they were lighter than the rollers I had. Before putting in the sliders, the belt was a bit low, and I was going to shave the boss, but now I don't have to. Assuming the belt CAN go any higher, if you are already as high as you should go, and you use sliders, you MIGHT have to add a shim to bring the belt down a little. Add 0.1mm of shim for every 0.2mm you want the belt to drop.  |

|

|

|

Post by scooter on Oct 26, 2014 16:46:10 GMT -5

I have no idea. I tried taking it all off but I saw no increase in performance, so I put it back on.

|

|

|

|

Post by scooter on Oct 26, 2014 15:43:50 GMT -5

My favorite clip was around 5:20 Lesson(s) learned: - Motorcycle safety goes a long way

- Remain defensive while riding

- and don't do stupid things while riding (same rules applies to passengers)

The one with the bus, right? I was just looking again and at 6:25 it looks that car definitely ran that scooter off the road and into the guard rail or at least scared him into the rail by getting too close. The car moved over because a car on the other side of the road was passing. lol a chain reaction. |

|

|

|

Post by scooter on Oct 26, 2014 14:21:40 GMT -5

On this GY6, I like going 50.

55 is nice, and is probably the speed I go most often, but the engine is starting to rev high enough that I'm afraid I'm reducing its longevity, even if just a little. (About 7500 rpm)

At 60, I'm revving a bit too high and frankly I'm thinking the bike just isn't safe at that speed.

I like speed. On a bigger bike, I might enjoy gong 80, or 100 or more if getting a ticket were of no concern, but on the 150cc, 50mph is as fast as I can go without feeling concerned about safety or guilty about what I'm doing to the bike.

|

|