|

|

Post by dmartin95 on Oct 24, 2014 2:43:26 GMT -5

I'm considering getting an electronic fuel pump for my scooter.

What do you recommend for PSI?

How many Liters/Gallons per hour?

(on average) How much fuel does a stock 150cc use at max throttle for 1 hour?

|

|

|

|

Post by scooter on Oct 24, 2014 4:36:10 GMT -5

I'm considering getting an electronic fuel pump for my scooter. What do you recommend for PSI? How many Liters/Gallons per hour? (on average) How much fuel does a stock 150cc use at max throttle for 1 hour? I don't know why people would want an electric fuel pump because it seems like it's adding a fail point but.. I get about 100 kilometers per gallon or 62mpg I think, and can go 60mph, so I think I'm pumping at least 1 gallon per hour and that's on average. At full speed I don't know, but I'd say I spen most of my riding time at or near full throttle. I know I don't have your answers but I wanted to join in the conversation and see what people have to say. |

|

|

|

Post by dmartin95 on Oct 24, 2014 12:39:57 GMT -5

I don't know why people would want an electric fuel pump because it seems like it's adding a fail point but.. In short, it's because one of my Scooters (actually my wife's) is the ole Retro style and has the fuel tank in the floor board (the bottom of the scooter and well below the carb) and cuts out at wide open throttle. I was thinking about getting this fuel pump: K&N 81-0401

--------------------------- I recently repaired a vacuum line I thought may have been the problem and finally got a good day to test the fix.... It was still cutting out... I have a Muikini vacuum operated pulse pump that I'm going to try and if that doesn't fix it, I'm going with an electronic fuel pump or a gravity fed fuel tank.  |

|

|

|

Post by rcq92130 on Oct 24, 2014 12:54:15 GMT -5

Just did that.

Pump I got seems to work OK - but mine is rated at 5 to 8 psi, which is on high for the little needle valves in these things. Have ordered another at 2 to 4 psi, more sensible. Either one is about $20 delivered.

Hook it up with a relay energized by something that gets +12V when ignition is "On" - not directly from the ignition source.

Downside: My ammeter used to hover around 14v when riding, now down to 12v. Current drain MAY (?) be a bit much for the teensy stators on these things. Not sure yet.

As for "scooter's" comment:

My vacuum operated P.O.S. pump failed after 3 months. THAT is a source of failure. In fact - the entire notion of bleeding off manifold vacuum seems stupid to me, as is the idea these vacuum pumps will necessarily do all that is needed, reliably, at WOT. Electric is fine in those situations, and - if you ever have to empty the carb bowl of fuel, you will not be cranking for a day to get the engine to first start.

|

|

|

|

Post by alleyoop on Oct 24, 2014 14:24:57 GMT -5

The real problem is with those fuel tanks that are mounted on the floorboard and have the fuel outlet on top of the tank, You would be better off to take the tank off and have a outlet welded on the bottom. Then you could lower the fuel pump even with the outlet and gas would always be at the fuel pump to pump forward and you would not have any starvation of fuel when running at wot for any length of time.

Really bad design those depend on suction to start the flow of fuel and any disruption of suction the flow of fuel will stop.

Alleyoop

|

|

|

|

Post by scooter on Oct 24, 2014 16:17:59 GMT -5

I don't know why people would want an electric fuel pump because it seems like it's adding a fail point but.. In short, it's because one of my Scooters (actually my wife's) is the ole Retro style and has the fuel tank in the floor board (the bottom of the scooter and well below the carb) and cuts out at wide open throttle. I was thinking about getting this fuel pump: K&N 81-0401

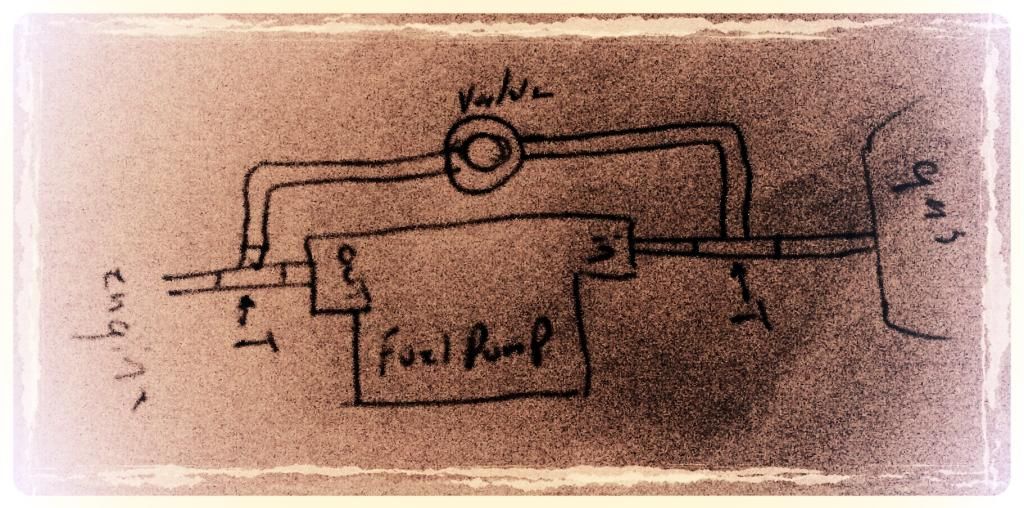

--------------------------- I recently repaired a vacuum line I thought may have been the problem and finally got a good day to test the fix.... It was still cutting out... I have a Muikini vacuum operated pulse pump that I'm going to try and if that doesn't fix it, I'm going with an electronic fuel pump or a gravity fed fuel tank.  I, too, have the tank in the floor and a vacuum pump. I had the same problem. At WOT, after some seconds, it would choke out and bog and I'd have to let off the throttle for several seconds to get it to work right again. I don't know what cured it. I replaced all of the vacuum lines and cleaned the carb and it stopped doing that. Initially, it may have been due to a loose intake manifold. As a note, my fuel outlet is on the bottom of the tank. Additional note, it cranks up rather quickly after a carb cleaning. The little pump really makes the fuel go. spurt! spurt! spurt!  I took it apart back when I was trying to figure out the bogging problem but found nothing wrong with it. I guess it got a cleaning if nothing else. That scooter I just fixed up has the tank up high and one of these:  And my own scooter has the tank down low and one of these:  |

|

|

|

Post by scooter on Oct 24, 2014 16:34:12 GMT -5

Just did that. Pump I got seems to work OK - but mine is rated at 5 to 8 psi, which is on high for the little needle valves in these things. Have ordered another at 2 to 4 psi, more sensible. Either one is about $20 delivered. Hook it up with a relay energized by something that gets +12V when ignition is "On" - not directly from the ignition source. Downside: My ammeter used to hover around 14v when riding, now down to 12v. Current drain MAY (?) be a bit much for the teensy stators on these things. Not sure yet. As for "scooter's" comment: My vacuum operated P.O.S. pump failed after 3 months. THAT is a source of failure. In fact - the entire notion of bleeding off manifold vacuum seems stupid to me, as is the idea these vacuum pumps will necessarily do all that is needed, reliably, at WOT. Electric is fine in those situations, and - if you ever have to empty the carb bowl of fuel, you will not be cranking for a day to get the engine to first start. Personally, one of the things I like about these scooters is that they can be kick started and need no battery. That's a handy feature if you're stuck out in the boonies and need to get home. I may not be able to build a generator to charge a dead battery left to drain by some idiot, namely me, but I can kick on the starter. Sorry you got a bad pump. I suppose mine may go bad at any time. Perhaps I should carry a container and a piece of fuel line in my tool kit.  |

|

|

|

Post by xyshannen on Oct 24, 2014 21:23:42 GMT -5

Scoot I have the same problem...well I did before my build.. I haven't had a chance to run this motor hard enough to see if I still have an issue. A dirty pump was probably your problem. These pumps (just like yours) are prone to build up from cheap/ethanol gas, that also causes issues. But that's just one of several problems with this setup. IMO the whole system is really just flawed to begin with. I to don't understand why the manufactures don't just put an electric pump on these things to begin with. It's not like it would effect the cost of production much. I know when you are talking about mass produced items how a few bucks more adds up to BIG $ in end production costs. I just assume they pass the cost down to the end user. I mean what instead of my scoot costing 1399 it costs me 1420. I would rather pay 20 bucks more for my scoot to be that much more reliable.

|

|

|

|

Post by rcq92130 on Oct 24, 2014 21:31:30 GMT -5

|

|

|

|

Post by scooter on Oct 26, 2014 18:53:26 GMT -5

As for "scooter's" comment: My vacuum operated P.O.S. pump failed after 3 months. THAT is a source of failure. In fact - the entire notion of bleeding off manifold vacuum seems stupid to me, as is the idea these vacuum pumps will necessarily do all that is needed, reliably, at WOT. Electric is fine in those situations, and - if you ever have to empty the carb bowl of fuel, you will not be cranking for a day to get the engine to first start. I am beginning to understand the vacuum system a little better. Seems opening the throttle plate produces a giant hole in our engine's "vacuum box", so when we are at WOT, the "leak" is at its worst, and right at the time when need the most fuel. This would also suggest that using a carb that is too big will create vacuum issues. I suppose using an external vacuum pump for the fuel pump would be one way to fix it, but an electric pump sounds like an easy and simple alternative. dmartin95 rcq92130 alleyoop xyshannen |

|

|

|

Post by xyshannen on Oct 26, 2014 19:34:10 GMT -5

scooter I'm thinking the same thing. Just we have two factors to worry about, 1 the pump not providing enough fuel, 2 The pump pushing too much fuel. The second is actually the easiest to deal with. A simple in-line fuel regulator should solve the problem. But until one of use attempts this upgrade wee just don't know what's going to happen. At 20-30 gph the pump rcq92130 linked should be more than sufficient. rcq92130 I never really trust stats on anything I buy from the bay. They are often either inflated or reduced, depending on what makes said product look better to the consumer. If I were you I would test the new pump prior to installation. Get a bucket and an empty gallon milk jug and see how long it takes the pump to fill the jug. Then calculate the pumps actual gallon per hour rating.

|

|

|

|

Post by alleyoop on Oct 26, 2014 19:57:36 GMT -5

If your gas tanks fuel outlet is on top it works just like if you siphoned some fuel out of a cars tank. What do you do, you stick a hose down the gas tank and to start the gas flowing you suck on the hose AND HOLD IT DOWN if you hold it up it will stop flowing.

So be smart lower the pump below the fuel outlet and let the fuel flow down to the pump, don't worry the vacuum fuel pump has enough force to pump it up to your carb. The problem on those scoots is that they mounted the fuel pump HIGHER than the fuel tank and fuel does not flow up very well.

Alleyoop

|

|

|

|

Post by scooter on Oct 26, 2014 21:45:43 GMT -5

scooter I'm thinking the same thing. Just we have two factors to worry about, 1 the pump not providing enough fuel, 2 The pump pushing too much fuel. The second is actually the easiest to deal with. A simple in-line fuel regulator should solve the problem. But until one of use attempts this upgrade wee just don't know what's going to happen. At 20-30 gph the pump rcq92130 linked should be more than sufficient. rcq92130 I never really trust stats on anything I buy from the bay. They are often either inflated or reduced, depending on what makes said product look better to the consumer. If I were you I would test the new pump prior to installation. Get a bucket and an empty gallon milk jug and see how long it takes the pump to fill the jug. Then calculate the pumps actual gallon per hour rating. Oh, man, 20-30 gph. I'd bet 2gph would be more than enough. Yes, like rcq, I'd be concerned the pump would overpower the needle valve. I have no idea how much pressure they could take before being forced open. I don't know how a regulator works but I suppose one could run a fuel return line back to the tank with an adjustable valve or a restriction in it to let off and adjust pressure. You might even be able to run the return hose to a Y on the pump's intake side, although I suppose having the fuel recirculate in such a short loop might build up a little heat, but it sounds negligible. If I were only testing, I might skip the valve and run the line to the tank vent with or without some restriction in it.  I just thought of something while I was talking to gregory. It occurred to me that one change I did make, while rehoseing (is that a word? if not I call it!) my vacuum system, was that I put the fuel pump on one of the intake nipples by itself. I have two. The canisters are on one line with y connectors, and the fuel pump is by itself on the other side. It seemed to me that something as important as the fuel pump should not be sharing leaks and pressure variations with other components. Who knows if that made any difference. So that's 3 things I changed leading to what is now a good working engine. Tightened the intake manifold. Cleaned the fuel pump. Put in new vacuum lines. Put the fuel pump on an intake vacuum nipple by itself. |

|

|

|

Post by rcq92130 on Oct 26, 2014 21:58:55 GMT -5

Far as I know, your gas tank is under the floor (like mine), and the OEM location of the vacuum pump is half way up towards the carb. That may be part of the issue with a vacuum pump - too high above the tank. It also made first start REALLY difficult, waiting for the pump to fill the fuel bowl of the carb.

I have ZERO worry about the pump delivering enough fuel for this little motor. Rather, I am worried about the pressure being too high and overpowering the needle valve (forcing too much fuel into the bowl). Might try a regulator at some point ... but will first wait to see if the new pump (with a lower set point on pressure) seems more agreeable.

|

|

|

|

Post by xyshannen on Oct 26, 2014 22:29:14 GMT -5

scooter My original setup was just like yours and had the problem. My current setup even did away with the shared vacuum line to the carb. I have one nipple on my intake and that powers my fuel pump, and nothing else. Now add to the mix my tunnel ram intake that actually increases velocity and should add more vacuum or at least help matters, and the problem is still present. Granted I can now go much faster at greater RPMS before it happens. Testing today showed me I can run 7500 RPMs for about 5 minutes before I cut out, and with my current setup that's cruising at a lil over 60 mph. I love this new setup...7500 rpms and 60 mph is only about 1/4 throttle @ cruising.  A regulator is designed to supply the amount of fuel needed by an engine at any given RPM. No need to reroute excess fuel because there isn't any, the pump just keep pumping regardless if it's total volume of fuel is being used or not. At worst you might get pressure buildup in the line between the pump and the regulator, But you would need to have one damn strong pump for that to be a problem. One stronger than the little pump we would use in our application. Just make sure you have line clamps on your lines and that they are in good condition and not dry rotted. rcq92130 Fuel pumps like this should be designed to handle back pressure caused by a regulator. Very few setups out there will use exactly the amount of fuel a pump provides. As long as it's within reason and fuel is actually moving through the pump it shouldn't burn up.

|

|