|

|

Post by rcq92130 on Mar 18, 2015 18:49:02 GMT -5

Good comments. This was to be a comparison of the different variators out there, to help some day in selecting new ones ... which are good, which not so good, and why. There are lots of writeups about how to TUNE the thing after you have already bought one, but only anecdotal comments on which is "best". I hoped this would become a sort of library - with people adding lines as they measure their own variators. Then we all could buy smart. About tuning: Though there are lots of write ups about tuning, I have not found any that are very good. Maybe the authors skip too much, or maybe they actually don't understand all that well what they are doing. It occurs to me YOU could write a GREAT step-by-step everyone could understand and follow to get the most out of their engine. It would be a really good long-term way of 'giving back'. Maybe think about it? Very good info rcq. When you measured the variator weight , what all did you weigh? Did you only weigh the variator or the whole assembly together ? Weight of each piece was separate. Didn't think of weighing the bosses. But I seriously doubt weight is relevant to anything. |

|

|

|

Post by geh3333 on Mar 18, 2015 19:00:13 GMT -5

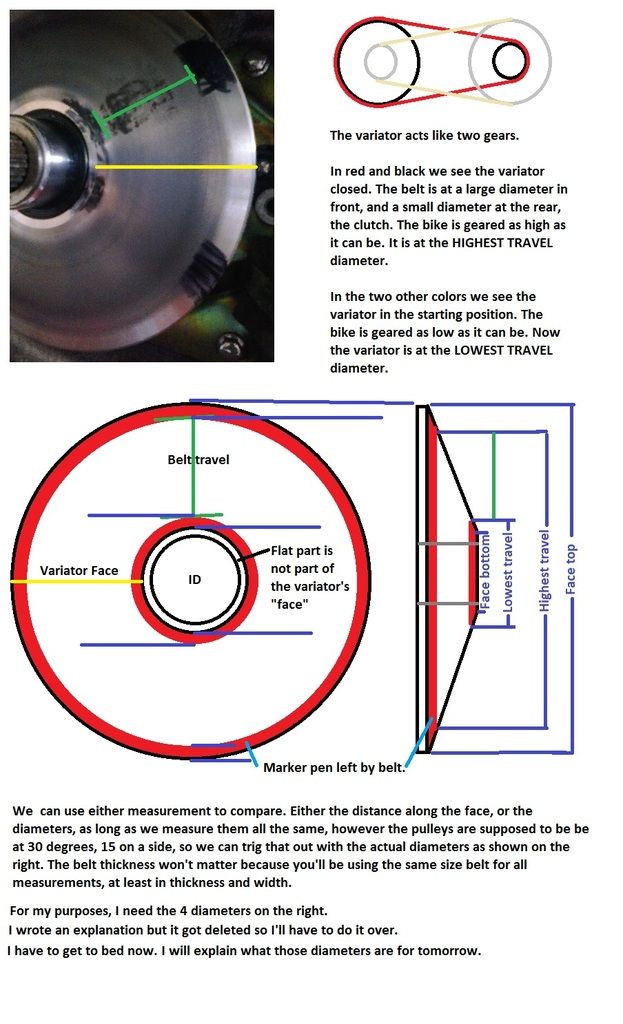

NOW ON TO THE VARIATOR ITSELFSOME VERY INTERESTING MEASUREMENTS, I THINK. Here is a diagram so we are all talking about the same things:  So here are the comparisons ................................................... OEM....................... Dr. Pulley ............... el Cheapo1. Overall sizes E: Diameter .......................... 107.4mm ................. 114.7mm .............. 115.2mm H: Thickness ......................... 35.7mm .................. 35.6mm .............. 35.7mm D: Boss diameter ................. 24mm .......................24mm ................ 24mm The thickness of all three is the same. 2. Belt Travel DistanceOne of the most important things is the overall distance on the face of the variator over which the belt can travel. Of course this is influenced by the overall size of the variator (107mm or 115mm). But it's also changed by the two 'dead zones' - one at the center of the variator (belt cannot drop lower than this) and one at the edge of the variator (belt cannot rise higher than this). Here are the interesting results: ................................................... OEM...................... Dr. Pulley ............... el CheapoC: Inner Dead Zone .................. 4.14mm ................. 3.76mm .................. 4.57mm A: Outer Dead Zone .................. 3.96mm ................. 3.56mm .................. 5.94mm Thus, the USABLE BELT TRAVEL DISTANCE IS (each side): B: ...........................................35.13mm ................39.54mm ............... 36.77mm

This is important because it gives you the most "gears" when the usable distance is longer. This can be used to give you more low end or more high end.

The USABLE belt distance of the 115mm el Cheapo is only slightly better than the smaller, 107mm OEM variator !!!!!!!! The thing here is the diameter. Getting the belt out to 115mm will give you more top end speed than the 107.

107 - 3.96*2=99.08 and

115 - 5.94*2=103.12.

If you shave the face of the boss or sheave a little, you could go all the way out to the edge, and if you put in shims, you could go all the way down until your belt hit the boss. These are extremes of course and not desirable. For top speed, IF your motor can push it, the oem is inferior, the el cheapo is much better, and the DP wins over the EC.

We already know the DP and the EC can give more top end. Without cutting or shimming, we see the DP has the smallest lower end dead zone, BUT what we really need to know is the diameter where the inner dead zone begins. The smallest diameter will give us the lowest starting "gear".3. RAMP SIZEThe depth of the ramps (at the hub) are not all the same, and the "length" of the ramp (distance from hub to outer extremity of the ramp are also not the same. The depth depends on how thin the variator is at the hub. The lengthdepends on how thin the VERTICAL EDGE is on at the outer edge of the ramp. A deeper ramp (at the hub) allows for more dramatic movement of the sliders/rollers. The length of the ramp does the same. So here are the measurements: ................................................... OEM....................... Dr. Pulley ............... el CheapoG: Ramp Depth (at hub) ........... 30.2mm .................. 29.37mm ................ 28.58mm I: Ramp length (hub to edge) .... 26.99mm ................. 31.57mm ................ 29.27mm The OEM has a nice, deep cut ramp - but of course it's short (since the thing is only 107mm diameter). el Cheapo is both cut not as deep and is not as long (because the side wall of the variator is thicker). It's a loser on BOTH counts. This is where it gets complicated. This is a calculus problem. We need to know the rpm at any given point on the pulley face. You have w weight at x diameter traveling at y rpm on z ramp angle, but that only tells us how much force the rollers will exert on the movable pulley. What also matters is what the engine needs, and what you want. It needs the belt to rise when it reaches the rpm that you decide it needs to move at, at any given speed, on a given road incline, and the way you want it to.

In my case, I wanted my engine to accelerate at 6,500 rpm when at WOT and to attain 7,500 rpm, with the belt all the way out, on level ground. If the ramp is too steep then the pulley will start to open at cruising rpm, resulting in high rpm cruising. If it is shallow then it may make the pulley close too soon as you take off, bringing your rpms to below what you want, resulting in poor acceleration.

The perfect variator would give you whatever rpm you want, at any speed, and also the maximum top end that your motor can pull at max HP, and a low cruising rpm. In other words it would be electronically controlled and adjustable on the fly for various driving styles and road conditions. The next best thing is a variator ramp that is tuned to your engine, bike, weight, and driving style.4. VARIATOR WEIGHTI'm with you on this. It's probably not a big deal.

Also don't forget that your back plate also has a width and a ramp angle which will affect performance. The rollers will be riding on the two ramps.

This also brings up sliders whose dimensions change depending on what angle they are at. That's a big deal and makes the math more intense.Anyway, there is the detailed comparison. Thanks, geh, for the motivation to look into this. It's odd we all have been flying blind about variators for so long. So, this is a start. Maybe others can add to the library so we can know what is really good or bad. Rcq is doing a great job with his research ! I only have a cell phone for internet right now so I'm really glad he is doing this . I now believe its probably best to buy all CVT and engine parts from PR. Scooter racing is very big down there and they would never use this junk being sold in the US. Many of these so called koso variators come with gouges , nicks and scratches all over the variator face. The DLH variator uses the same back plate with the same type print , checkered flag and coating. I would not be surprised if they are exactly the same all round. The shops in PR have a reputation to uphold and a quality good enough to supply the professional racers. The place I usually order from down there didn't even have these cheap Koso's when I checked. They had a few good looking variators from $40-$60 and some a little higher. They even have a black 117mm variator that I would like to try out. All the variator I looked at aren't as thick at the center where the boss inserts "just like my first koso" . I will soon order a new one and will have to post the results " performance wise " I have a feeling this thread will be active for a long time. |

|

|

|

Post by geh3333 on Mar 18, 2015 19:19:41 GMT -5

Moving on to the OUTER DRIVE FACEI have two - one from the OEM setup and the other from the Dr Pulley kit. Here are the two side by side:  Much larger cooling fins on the OEM face. However, this comes at the expense of weight: OEM ...................... 170 grams Dr Pulley ............... 142 grams Here is a photo of the faces of the two:  Notice TWO important differences: 1. The Dr Pulley face allows the belt to ride much closer to the hub. The OEM face has a 'flat section" milled onto the face - 7.9 mm of unusable area right next to the hub. The Dr Pulley design has it's curved, usable surface milled much closer to the hub. The belt is thus allowed to work on a smaller diameter, giving better low end performance. 2. The Dr. Pulley face has a 1mm "lip" causing it to stand off that much further from the inner drive face. This ALSO causes the belt to run lower in between the faces. However, the same could be accomplished with a washer with the OEM design. It isn't known if the dr Pulley variatior ramp design somehow makes up for this extra 1 mm separation at HIGH speeds. The thickness of the faces - from the point where they touch the inner drive face, on one side (INCLUDING the lip) to where the nut contacts the face on the other side, are identical: OEM ................... 8.7 mm Dr Pulley ............ 8.7 mm Rcq, ignore my post about what all you weighed. I have 4 koso variators now and I just noticed there are 3 different styles ! The first one I ever bought weighs 264grams the second one weighs 274grams the third weighs 291grams and my new one weighs 291grams. Soooo , I'm sure koso isn't making all of these variators and just making mistakes . I never measured the weight on the second one I bought , I just thought it was the same as the third and fourth one . this tells a lot , and that is that there are a number of fakes . |

|

|

|

Post by rcq92130 on Mar 18, 2015 23:20:03 GMT -5

Moving on to the OUTER DRIVE FACEI have two - one from the OEM setup and the other from the Dr Pulley kit. Here are the two side by side:  Much larger cooling fins on the OEM face. However, this comes at the expense of weight: OEM ...................... 170 grams Dr Pulley ............... 142 grams Here is a photo of the faces of the two:  Notice TWO important differences: 1. The Dr Pulley face allows the belt to ride much closer to the hub. The OEM face has a 'flat section" milled onto the face - 7.9 mm of unusable area right next to the hub. The Dr Pulley design has it's curved, usable surface milled much closer to the hub. The belt is thus allowed to work on a smaller diameter, giving better low end performance. 2. The Dr. Pulley face has a 1mm "lip" causing it to stand off that much further from the inner drive face. This ALSO causes the belt to run lower in between the faces. However, the same could be accomplished with a washer with the OEM design. It isn't known if the dr Pulley variatior ramp design somehow makes up for this extra 1 mm separation at HIGH speeds. The thickness of the faces - from the point where they touch the inner drive face, on one side (INCLUDING the lip) to where the nut contacts the face on the other side, are identical: OEM ................... 8.7 mm Dr Pulley ............ 8.7 mm Rcq, ignore my post about what all you weighed. I have 4 koso variators now and I just noticed there are 3 different styles ! The first one I ever bought weighs 264grams the second one weighs 274grams the third weighs 291grams and my new one weighs 291grams. Soooo , I'm sure koso isn't making all of these variators and just making mistakes . I never measured the weight on the second one I bought , I just thought it was the same as the third and fourth one . this tells a lot , and that is that there are a number of fakes . So, geh - the thought I had with this is that maybe all of us together can, over time, pull together enough data that we can take care of ourselves and make sure we get what we want and need. That's pretty difficult at this point. Best one can do is buy from a trusted source - mine are the same as yours (Gy6Racing and John) - but even then we are dependent on someone else looking out for us when we should look out for ourself. That's why I suggested to JerryScript this morning the possibility of starting a table in the "data" section of this blog - a place where we can start listing all the variators any of us have and their measurements. Might take a while but if every so often someone else would add another line for their new variator I think is due course we would have the best library of variator data in existence. Maybe that's a dumb idea - so I'm asking for your opinion. |

|

|

|

Post by rcq92130 on Mar 18, 2015 23:29:16 GMT -5

Dr Pulley and el cheapo - identical overall height and slope  All 3 drive faces:  Outer drive plates:  All 3 glide plates:  But all have identical angles:  |

|

|

|

Post by geh3333 on Mar 18, 2015 23:37:39 GMT -5

Rcq, ignore my post about what all you weighed. I have 4 koso variators now and I just noticed there are 3 different styles ! The first one I ever bought weighs 264grams the second one weighs 274grams the third weighs 291grams and my new one weighs 291grams. Soooo , I'm sure koso isn't making all of these variators and just making mistakes . I never measured the weight on the second one I bought , I just thought it was the same as the third and fourth one . this tells a lot , and that is that there are a number of fakes . So, geh - the thought I had with this is that maybe all of us together can, over time, pull together enough data that we can take care of ourselves and make sure we get what we want and need. That's pretty difficult at this point. Best one can do is buy from a trusted source - mine are the same as yours (Gy6Racing and John) - but even then we are dependent on someone else looking out for us when we should look out for ourself. That's why I suggested to JerryScript this morning the possibility of starting a table in the "data" section of this blog - a place where we can start listing all the variators any of us have and their measurements. Might take a while but if every so often someone else would add another line for their new variator I think is due course we would have the best library of variator data in existence. Maybe that's a dumb idea - so I'm asking for your opinion. Great idea , that way everyone gets what they ask for . |

|

|

|

Post by geh3333 on Mar 19, 2015 0:49:29 GMT -5

This would also give sellers an idea of what types and brands of variators to sell . when if comes to such an imolportant part like the variator , it helps to have an idea of what performance one type of variator brings compared to others. Also what type of quality they will receive. Obviously something is going on with the koso variators being sold. They use to be very good variators but over the past yr or so something has changed or is being faked by many. Either way its a problem. It would be fine if they actually performed the way they are meant to , but when you buy a variator that will not let the belt drop fully and at the same time it will not let the belt rise fully its a problem . this tells you that someone is pumping these things out without any true knowledge of the product , they are only trying to make money by using the koso name. Gouges , and nicks on the variator face will eat the belt quicker and should never even be sold. I wouldn't be surprised if they weren't even balanced . I like to see a test done to see how far off they are. On atleast two of my variators the belt line at the top of the variator is uneven , this may even eventually cause crank issues.

|

|

|

|

Post by scooter on Mar 19, 2015 4:51:55 GMT -5

Rcq is doing a great job with his research ! I only have a cell phone for internet right now so I'm really glad he is doing this . I now believe its probably best to buy all CVT and engine parts from PR. Scooter racing is very big down there and they would never use this junk being sold in the US. Many of these so called koso variators come with gouges , nicks and scratches all over the variator face. The DLH variator uses the same back plate with the same type print , checkered flag and coating. I would not be surprised if they are exactly the same all round. The shops in PR have a reputation to uphold and a quality good enough to supply the professional racers. The place I usually order from down there didn't even have these cheap Koso's when I checked. They had a few good looking variators from $40-$60 and some a little higher. They even have a black 117mm variator that I would like to try out. All the variator I looked at aren't as thick at the center where the boss inserts "just like my first koso" . I will soon order a new one and will have to post the results " performance wise " I have a feeling this thread will be active for a long time. I agree he's doing well and it should be a focus for us. A couple of things I will add is that the "ramp depth" is not a good way to measure. The weights don't ride on the hub. Making it longer just reduces the travel, but it's a non issue because all that matters is that the back plate ramps are touching the weights. That means that the longer you make the hub, the thicker the front of the variator needs to be. The proper way to measure the effectiveness of the ramps is to measure the plate ramps, rollers, boss, variator pulleys, clutch shift angle (that curved hole in the clutch hub), and clutch main spring, as one unit, along with the engine. Even then, as we have all seen, the system can be so highly geared that it becomes poorer in performance, because what good are higher gears if you can't pull the load? That's why we've had to reduce our weights so much on some of these variators. Even then we may not have the power to reach maximum rpms. That's why it's nice that the Dr Pulley variator came with shims, so the rider can reduce gearing if need be. It's hard to nail this stuff down for all scooters because rider weight and riding style are factors too. My preference would be a variator that goes all the way down into the pulley, for best off the line acceleration, keeping the rpms at maximum torque and power, making the belt go just high enough that I can still reach max rpm. That may mean a variator that actually never closes all the way. Let's say you change the cam and give yourself more power at certain rpms. Now your variator needs to match that. The ramp "depth" depends on the diameter of the variator. The larger the diameter, the more distance the pulley must move in and out. If the belt is 120mm wide, then you want the pulley faces, at the bottom and at the top, to be roughly 120mm apart so that the belt can travel the entire face of the variator, or close to it. The easiest way to test a variator's travel is to assemble it and mark it and run it. Then you'll have your two diameters. RCQ talked about travel. Travel is not the distance from the ends, it is the distance between the two marks. On the DP variator the travel is: (114.7 - (3.56*2))-(3.76*2)=(107.58-7.52)=100.06mm /2=50.03mm per side (But this assumes that the pulleys are all made the same. That's why knowing the actual diameter at the bottom is important, not the "dead zone".) We already know this is not going to be accurate but let's continue. On the OEM the travel is: (107.4-(3.96*2))-(4.14*2)=(99.48-8.28)=91.2mm /2=45.6mm per side And on the EC the travel is: (115.2-(5.94*2))-(4.57*2)=(103.32-9.14)=94.18mm /2=47.09mm per side I see those numbers don't match RCQ's so one of us goofed, but again, you need the inner mark diameter to know the real travel. The good news, assuming the variators are all cut at the exact same angle, is that he can directly measure the distance between the two marks for a comparison. He can get the real travel by measuring the outer mark diameter and subtracting the inner diameter. The other difference is gearing. The outer marks show us which pulley has the highest gear. That would be the DP at 100.6, the EC at 94.18, and the OEM at 91.2mm. That's 4.7mm per side difference between his OEM and the DP. I think he could add 2.35mm or about .094" of shim to make the gearing the same at top end. He has 3.76mm of inner dead zone, but he could only add 1.88mm or .075" of shim before his belt hits the bottom of the variator face. Don't hold me to that. As I recall, at 30 degrees pulley, you get about 2mm drop for every 1mm of shim. If those numbers are correct, then he could drop the belt to the bottom of the variator face and his top end would be 46.54mm - 45.6mm = .94mm higher than the OEM. So he'd get a higher top speed with the DP if his engine can pull it, and we need the actual inner mark diameter to see how it would affect the low end gearing compared to the other pulley. In other words, he needs to dump his travel figures and use the diameters to get the true travel, then he can figure out how shims would affect performance on the high and the low end. We already know he can get more top end with the DP, but now we need to know what the low end will be, and we need the inner mark diameters to find out. Good work RCQ! You too Geh! |

|

|

|

Post by rcq92130 on Mar 19, 2015 9:47:57 GMT -5

Scoot! This is actually becomming an interesting conversation!

1. The original intent was to characterize the HARDWARE since geh found that there are so many counterfiets out there, even among good retailers, it's become hard to know what we are getting. That is a DIFFERENT subject from how an individual properly TUNES the hardware he has bought.

2. Measuring the "inner distance", etc., are a little complicated.

Inner distance: the very inner few mm of the variator are flat, not sloped. The "innder dead zone" is mostly here. Then there is the long part of the face that is slanted (but, to my surprize, a constant angle - the cut of the face is NOT a compound, curved cut - simply flat at an angle --- try a straight edge to check). Then, finally, the outer dead zone - which is part of the same sloped face at the same angle

To measure the inner dead zone you need to first put a boss in and measure from it's edge. The hole in the middle of the variator isn't the same, as the bushing inside is not flush with the hole in the variator. You then have to triangulate a little because that measurement is on the flat, not on the same plane as the long, belt-riding angled surface. THEN you have the actual distance from the boss, on an angle, to the outer edge of the inner dead zone. ON THE ANGLE OF THE CUT FACE, not on the flat. Then from there out, on the same angle, you can measure the usable distance and the outer dead zone. These all added up will not equal the measured diameter of the variator since THAT is taken "on the flat" - the SLOPED distance is longer.

3. Performance, like you say, includes a bunch of other things like shims (and other variator set up issues), the clutch, gearing, rider weight, etc. That's a GREAT topic for a second writeup. The only one IU could find here was one from Alley that was really not all that bad - pretty good - but far from enough, not covering half of what you just mentioned. Maybe consider tackling that topic?

|

|

|

|

Post by scooter on Mar 19, 2015 15:42:09 GMT -5

Scoot! This is actually becomming an interesting conversation! 1. The original intent was to characterize the HARDWARE since geh found that there are so many counterfiets out there, even among good retailers, it's become hard to know what we are getting. That is a DIFFERENT subject from how an individual properly TUNES the hardware he has bought. 2. Measuring the "inner distance", etc., are a little complicated. Inner distance: the very inner few mm of the variator are flat, not sloped. The "innder dead zone" is mostly here. Then there is the long part of the face that is slanted (but, to my surprize, a constant angle - the cut of the face is NOT a compound, curved cut - simply flat at an angle --- try a straight edge to check). Then, finally, the outer dead zone - which is part of the same sloped face at the same angle To measure the inner dead zone you need to first put a boss in and measure from it's edge. The hole in the middle of the variator isn't the same, as the bushing inside is not flush with the hole in the variator. You then have to triangulate a little because that measurement is on the flat, not on the same plane as the long, belt-riding angled surface. THEN you have the actual distance from the boss, on an angle, to the outer edge of the inner dead zone. ON THE ANGLE OF THE CUT FACE, not on the flat. Then from there out, on the same angle, you can measure the usable distance and the outer dead zone. These all added up will not equal the measured diameter of the variator since THAT is taken "on the flat" - the SLOPED distance is longer. 3. Performance, like you say, includes a bunch of other things like shims (and other variator set up issues), the clutch, gearing, rider weight, etc. That's a GREAT topic for a second writeup. The only one IU could find here was one from Alley that was really not all that bad - pretty good - but far from enough, not covering half of what you just mentioned. Maybe consider tackling that topic? I'd be glad to go in depth on variators. They are my favorite part of the scooters. I was trying to express how complicated the shapes are, especially the ramps, and how the ramps, back plate, weights, boss length, and other measurements interact, so that it's difficult to examine any one part alone to figure out which one is "best". To measure the inner diameter, lay your calipers across the pulley from inside mark to inside mark. No need to worry about the angle. The view on the left side of the picture below shows the best way to measure. The view on the right is just for clarity. Same for the outside marks. The outside minus the inside diameters will give us the belt travel, tell us what your lowest gear is, what your highest gear is, and if you also include measurements of the OD and the face ID, not the flat part, we can then tell how much we can gear up or down with shims, or by cutting the boss, or even the pulley for that matter. This way you can get a real comparison between the three variators and also find out if you can make the other two perform as well or better than your OEM. For my own analysis, I'd be grateful if you'd throw in those inner mark diameters so I can continue studying the variators you have. That's very cool of you to post all of that. (btw I have considered making the face a different angle because the belt mfg said they can be X amount of angle from nominal. That could be useful. A compound angle would be cool but may wear the belt out by flexing it from one angle to another over and over again.) Thanks RCQ.  |

|

|

|

Post by rcq92130 on Mar 19, 2015 21:00:46 GMT -5

Hey Scoot! Your comments are GREAT! I think this is where we are getting different results:  The actual belt travel is ALONG THE SLANT, not on the flat (radial) distance). Also - on the 3 variators i checked the very inner part, next to the boss where the 'inner dead zone" is ----- this is a small FLAT cut portion of the face, NOT cut on the slant. The diagram above shows this. I note the earlier diagram i posted shows this incorrectly. THAT is why I was suggesting doing the trig to get the distance you would measure with calipers - as your correctly suggest - translated into an imaginary extension of the sloped face so that all the measurements are taken on the same plane. The OUTER dead zone does not havet his problem since the slant is cut all the way to the very edge of the variator, INCLUDING the outer dead zone. You didn't respond about writing up a "Variator Tuning Tutorial". No interest? I think it would be invaluable to a ton of people. btw: I completely agree the actual cut of the ramps on the backside of the variator is key to performance. The only problem (for me, and why I didn't include this) is because the ramps ARE compound cuts. VERY complicated to describe or analyze or compare. So, all I did was a kind of "overview" - length and inner depth (which is an approximation for the "in-out" travel of the rollers, and thus the travel of the guide plate and thus the travel of the variator itself from full "inward" to full "outward"). ROUGH approximation, I know - but the best I could think of w/o going totally bonkers. |

|

|

|

Post by scooter on Mar 19, 2015 23:11:05 GMT -5

Hey Scoot! Your comments are GREAT! I think this is where we are getting different results:  The actual belt travel is ALONG THE SLANT, not on the flat (radial) distance). Also - on the 3 variators i checked the very inner part, next to the boss where the 'inner dead zone" is ----- this is a small FLAT cut portion of the face, NOT cut on the slant. The diagram above shows this. I note the earlier diagram i posted shows this incorrectly. THAT is why I was suggesting doing the trig to get the distance you would measure with calipers - as your correctly suggest - translated into an imaginary extension of the sloped face so that all the measurements are taken on the same plane. The OUTER dead zone does not havet his problem since the slant is cut all the way to the very edge of the variator, INCLUDING the outer dead zone. You didn't respond about writing up a "Variator Tuning Tutorial". No interest? I think it would be invaluable to a ton of people. btw: I completely agree the actual cut of the ramps on the backside of the variator is key to performance. The only problem (for me, and why I didn't include this) is because the ramps ARE compound cuts. VERY complicated to describe or analyze or compare. So, all I did was a kind of "overview" - length and inner depth (which is an approximation for the "in-out" travel of the rollers, and thus the travel of the guide plate and thus the travel of the variator itself from full "inward" to full "outward"). ROUGH approximation, I know - but the best I could think of w/o going totally bonkers. Yes I'd love to do a tutorial. I can show you how to measure the ramps if you want. Here's what I need to continue my math on these three variators:  |

|

|

|

Post by geh3333 on Mar 20, 2015 1:41:47 GMT -5

I threw some sliders and a back plate on the Koso's I have , and inserted a boss into the variator . from there I measured how much of the boss was sticking out from the variators. I USed the same sliders , backplate and boss for each variator. What I found was the boss was sticking out about 1mm more with the lighter koso then the heaviest koso . I would imagine this means the face of the heavier koso is about 1mm thicker then the lighter one " my first koso " . this has to be the reason my belt will not drop fully without shims.

|

|

|

|

Post by geh3333 on Mar 20, 2015 14:50:28 GMT -5

Maybe at some point we will be able to tell what type of variator we have by weighing it or by how thick the face is , or both

|

|

|

|

Post by rcq92130 on Mar 26, 2015 22:45:48 GMT -5

Maybe at some point we will be able to tell what type of variator we have by weighing it or by how thick the face is , or both I have sent TWO emails to Koso asking simply if they make a variator kit for GY6 engines (their product list does NOT show any such product). The Koso people - being GREAT with customer support - have completely ignored both emails. |

|