Freshman Rider

Currently Offline

Posts: 67

Likes: 0

Joined: Apr 15, 2013 17:11:59 GMT -5

|

Post by justinbabcock1125 on Apr 19, 2013 1:41:20 GMT -5

I just might but the harbor freight goes up to 210 ...i hit it with a snap on large impact with 208...

|

|

|

|

Post by urbanmadness on Apr 19, 2013 1:48:18 GMT -5

Yup, I bought one too... best purchase I've made for working on scooters. That and the stator bell pullers and the starter nut socket. When my buddies come around wanting me to work on their scooters I tell them... Ok dude, the deal is you buy me a tool... =) The next buddies buying me 1/4 and 3/8 ratchets... good ones... like 40 and 80 bucks a piece..  ... I just tear up the cheap ones. |

|

New Rider

Currently Offline

Posts: 38

Likes: 0

Joined: Mar 4, 2013 3:38:11 GMT -5

|

Post by Moat on Apr 19, 2013 3:52:55 GMT -5

1) Make (nice job, chindog!), borrow or buy a proper variator locking/holding tool/spanner.

2) Soak the nut's threads repeatedly over an entire day or two, with penetrating oil (PBlaster, Kroil, Mouse Milk, Liquid Wrench, etc...).

3) Get the nut good and hot with a propane or Mapp gas torch. Smoking hot... but being careful that it's not hot enough to melt any aluminum variator part(s).

4) Immediately (while still very hot), and with the locking/holding tool securely in place, crank on it with a big 'ol breaker bar (1/2" drive, minimum) with a proper fitting socket installed (preferably 6 point).

I'd bet it comes right loose.

You might want to replace the crankshaft seal while you're in there, if the heat appeared to do it any damage.

|

|

New Rider

Currently Offline

Posts: 38

Likes: 0

Joined: Mar 4, 2013 3:38:11 GMT -5

|

Post by Moat on Apr 19, 2013 4:23:01 GMT -5

... there is a gizmo you can screw into the spark plug hole that keeps the motor from turning over... Contrary to seemingly popular (mis)conception, those tools are NOT intended to hold the piston/crankshaft in place for whatever tightening/loosening antics. Their true purpose is for precisely determining piston position BTDC/ATDC in order to calibrate a degree wheel, for cam/ignition timing purposes. Like the "rope trick", using one to keep the motor from turning over while loosening/tightening things is an invitation to big, big problems. Might be fine in a low-torque application on a weed whacker engine or the like - but not on something requiring this kind of force! |

|

|

|

Post by Jarlaxle on Apr 19, 2013 5:25:10 GMT -5

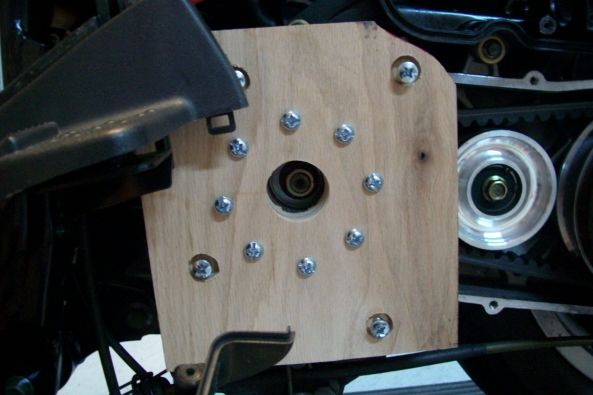

Here's my home made variator tool. The OEM tool for my Scarabeo was $150, so I just made one out of hardwood and bolts. It works just fine.  Any chance you could post a detailed "how-to" writeup in the appropriate forum? |

|

|

|

Post by Jarlaxle on Apr 19, 2013 5:29:09 GMT -5

1) Make (nice job, chindog!), borrow or buy a proper variator locking/holding tool/spanner. 2) Soak the nut's threads repeatedly over an entire day or two, with penetrating oil (PBlaster, Kroil, Mouse Milk, Liquid Wrench, etc...). 3) Get the nut good and hot with a propane or Mapp gas torch. Smoking hot... but being careful that it's not hot enough to melt any aluminum variator part(s). 4) Immediately (while still very hot), and with the locking/holding tool securely in place, crank on it with a big 'ol breaker bar (1/2" drive, minimum) with a proper fitting socket installed (preferably 6 point). I'd bet it comes right loose. You might want to replace the crankshaft seal while you're in there, if the heat appeared to do it any damage. A variation on that: heat the nut gently and carefully with a propane torch (or a heat gun on its highest setting)...then quench it with penetrating oil (PB Blaster, etc.) or synthetic engine oil. DO have a fire extinguisher handy when you do this! Let it cool completely. (You should be able to touch it with bare fingers.) Should pop right off...if not, repeat procedure. |

|

Freshman Rider

Currently Offline

Posts: 67

Likes: 0

Joined: Apr 15, 2013 17:11:59 GMT -5

|

Post by justinbabcock1125 on Apr 19, 2013 11:22:08 GMT -5

Well if i had 50 extra bucks i would but i spent to much already on this project if i spend anymore my ol lady would kill me lol

|

|

|

|

Post by nulldevice on Apr 19, 2013 18:54:41 GMT -5

Ive seen the wood tool before maybe ill make one but as for the rope trick no way i stated in my first post the rope trick snaped my piston but i need to get it off. Has anyone else ever delt with a nut that wont come off i hit it with 208lbs today an nothing it wont brake loose an im afraid if i try the wood tool ill brake something else Use an impact socket. my HF impact wrench came with sockets that fit the flywheel, variator, and clutch/rear sheave assembly of my 50/ 150, and 250cc Chinese scooters. If not, buy and use an impact socket preferably without any extensions. A question, are you squeezing the correct end of the trigger to remove the nut? Are you really sure? It is a right hand thread. |

|

Freshman Rider

Currently Offline

Posts: 67

Likes: 0

Joined: Apr 15, 2013 17:11:59 GMT -5

|

Post by justinbabcock1125 on Apr 19, 2013 21:49:15 GMT -5

Yes i work on stuff alot a impact is a tool i use alot

|

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 9

Joined: Apr 3, 2013 9:41:03 GMT -5

|

Post by mrpalmetto on Apr 20, 2013 10:42:10 GMT -5

All of you are a big help. I'.m thinking of playing Variator games and without these discussions i would not even think of trying. I just bought a 150KB and these boards have been VERY helpful. I had a banshee that was stolen out of my garage and they took my china 4 wheeler too, but left it 500ft from the hose. (Tired of pushing i guess). That's.been two years ago and never got the 4 wheeler to start again due to lack of spark. With all u'alls help i expect that to change soon. My hats off to alleyoop and new2scootn

|

|

|

|

Post by triker on Apr 20, 2013 10:51:13 GMT -5

My impact wrench that I use at work develops 650 pounds of torque. If it don't move It'll break.  Roy |

|

|

|

Post by alleyoop on Apr 20, 2013 12:38:02 GMT -5

Just take it to a garage and ask them to take the nut off. They will probably do it for nothing. Then tell them to put it on with just THREE ONE SECOND RAPS on the impact wrench start it up and give it a couple of revs and see if it does not come loose. If OK drive it back home and do your THANG  Alleyoop |

|