|

|

Post by scooter on Mar 21, 2015 16:24:11 GMT -5

HAHAHA! Nice move! That Morphous is a sweet looking ride! I want to try one out! It doesn't look anything like a Vespa, but as long as we're going crazy:  It looks like something Iron Man would ride. Mmmhmm he needs a moto-suit. the red one makes me think of tron I don't think I've seen the new Tron movie yet. I'll have to check it out. |

|

|

|

Post by scooter on Mar 21, 2015 16:22:17 GMT -5

HAHAHA! Nice move! That Morphous is a sweet looking ride! I want to try one out! It doesn't look anything like a Vespa, but as long as we're going crazy:  It looks like something Iron Man would ride. Mmmhmm he needs a moto-suit. That's Kaneda's ride from the film 'Akira'. As for Moto-suit...Check out season 3 of Robotech (The Invids) Why yes... there *is* a bit of anime geek in me...  I used to watch Robotech a long time ago. I loved that show. |

|

|

|

Post by scooter on Mar 21, 2015 8:57:01 GMT -5

HAHAHA! Nice move! That Morphous is a sweet looking ride! I want to try one out! It doesn't look anything like a Vespa, but as long as we're going crazy:  It looks like something Iron Man would ride. Mmmhmm he needs a moto-suit. |

|

|

|

Post by scooter on Mar 21, 2015 5:28:03 GMT -5

Arent jumper cables kind of a little too thick to be using for battery wires? What gauge wires should i be using? And the gas was mostly leaking out right between the muffler and the header pipe there was actually a small puddle starting to form on the ground and then i seen some wetness coming out of the very end of the muffler and when i did my compression test the tester had fuel in it when i hit the release a mist of fuel shot out and it was leaking out of the tester hose too also when i was checking for spark some mist of fuel shot out of the spark plug hole. How about switching from 15w40 conventional to 5w40 synthetic would that help at all? and is doubling up on the cylinder gasket the best idea or should i look at getting a higher performance starter? would i also need a high performance starter clutch? Find out how many amps you need. Here's a chart showing wire size for amperage and wire length. www.offroaders.com/tech/12-volt-wire-gauge-amps.htm |

|

|

|

Post by scooter on Mar 21, 2015 1:07:26 GMT -5

but you're the artist in the group so... Would you be willing to draw us a picture of an "updated" Vespa? Can you show us what a Vespa style scooter would look like if you made it aerodynamic and gave it "modern" lines, like car companies have been doing with cars like the Mustang? This is for anyone, but I know Leo has "the goods" to make it happen. No problem if you don't want to. It's practically scooter blasphemy, but I think it would be interesting to see. Who knows, maybe Vespa will take note. I must say what I see of their new scoots is a little blah, like an old washing machine on wheels, stuck halfway between then and now. Can you make it "sporty"? I may try it too but my drawing skills are not good.  I'm thinking "the Lamborghini of scooters" perhaps?  Cheesh, I just now saw this. I'll do it, but it may be a while. I'm pretty buried with health issues and work I need to do to keep the lights on. I'm not sure modernizing the Vespa would work too well, but I'll give it a try! Leo I hear you brother. Speaking of health issues, that Lamborghini is "sick"! |

|

|

|

Post by scooter on Mar 20, 2015 5:06:38 GMT -5

The frame should be good enough for a ground. If you feel your low beam is not good and your high beam is working well, then that would leave one or two wires coming from your low beam light to check out. Try bypassing one of the wires. If you have one ground for both lights then try bypassing the low beam positive wire by running it to the battery with another wire. If that does nothing then maybe it's your bulb. If it fixes the problem then look at the positive wire back to the handlebar switch and on to the battery. If the high and low are both dim then you might try bypassing your ground wire. Well, I have the bulb rewired to allow me to power the bulb by either the stator or the battery seperately. There is only one negative ground wire to the bulb. I have a switch in between the low beam positive and the bulb. The switch is hooked up to the low beam wire and the high beam wire on the bulb harness. Putting the switch in the middle turns the light off, turning it to the left or right connects the low beam power from the stator to the low or high beam individually. The light controls on the handlebar still function as normal, and only when I use the passing light button does it power the headlight bulb from the battery, but is bright either low or high beam when powered by the battery. I am using a halogen bulb, not that it matters much, but it does not seem to be worn out or anything. It just seems like the power to the dash and bulb is not right... Could a bad rectifier cause these symptoms? The only symptom from a bad rectifier I ever got was the power to running lights and dash would not come through at all, but that is not the case here. I'm not knowledgeable about the rectifiers. Jerry may be able to help you with that. |

|

|

|

Post by scooter on Mar 19, 2015 23:11:05 GMT -5

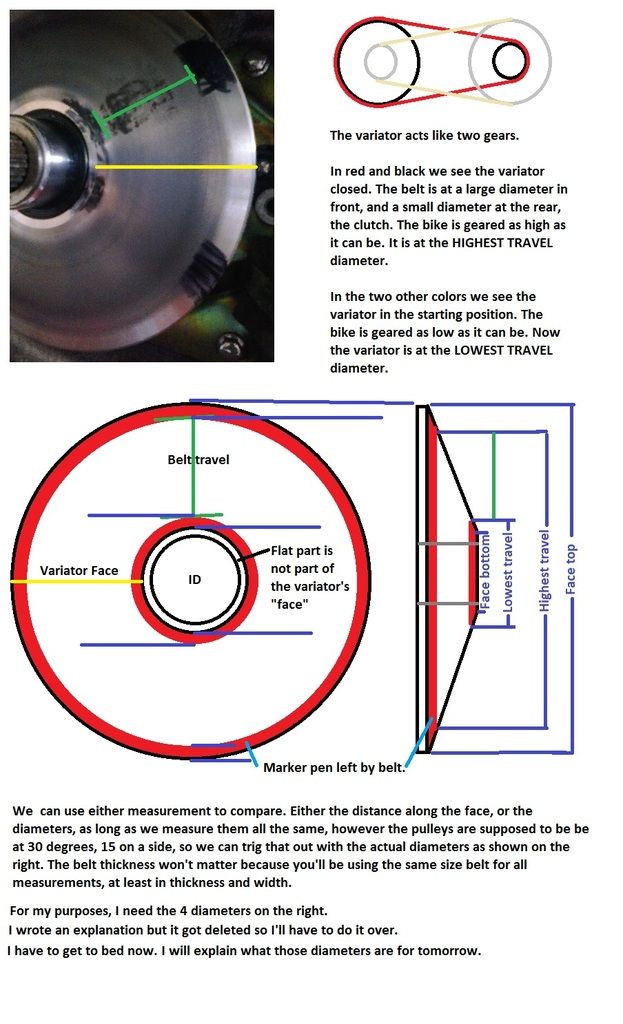

Hey Scoot! Your comments are GREAT! I think this is where we are getting different results:  The actual belt travel is ALONG THE SLANT, not on the flat (radial) distance). Also - on the 3 variators i checked the very inner part, next to the boss where the 'inner dead zone" is ----- this is a small FLAT cut portion of the face, NOT cut on the slant. The diagram above shows this. I note the earlier diagram i posted shows this incorrectly. THAT is why I was suggesting doing the trig to get the distance you would measure with calipers - as your correctly suggest - translated into an imaginary extension of the sloped face so that all the measurements are taken on the same plane. The OUTER dead zone does not havet his problem since the slant is cut all the way to the very edge of the variator, INCLUDING the outer dead zone. You didn't respond about writing up a "Variator Tuning Tutorial". No interest? I think it would be invaluable to a ton of people. btw: I completely agree the actual cut of the ramps on the backside of the variator is key to performance. The only problem (for me, and why I didn't include this) is because the ramps ARE compound cuts. VERY complicated to describe or analyze or compare. So, all I did was a kind of "overview" - length and inner depth (which is an approximation for the "in-out" travel of the rollers, and thus the travel of the guide plate and thus the travel of the variator itself from full "inward" to full "outward"). ROUGH approximation, I know - but the best I could think of w/o going totally bonkers. Yes I'd love to do a tutorial. I can show you how to measure the ramps if you want. Here's what I need to continue my math on these three variators:  |

|

|

|

Post by scooter on Mar 19, 2015 21:37:13 GMT -5

Is there a ground wire that leads up front from the battery? I had a bad ground. It wasn't visible in the wire but the meter said voltage was low. When I changed the wire, it worked great. I have a wire that goes from my battery to the frame like a couple inches away from the battery compartment which is under the floorboard. I suppose I should hook up a negative to the frame in the front as well. I am unsure as to what kind of stator it is. I have an 8 pole gy6 AC stator. I know the stator itself and the pickup are in good condition, and are relatively new. I installed it around the same time I installed my BBK. The frame should be good enough for a ground. If you feel your low beam is not good and your high beam is working well, then that would leave one or two wires coming from your low beam light to check out. Try bypassing one of the wires. If you have one ground for both lights then try bypassing the low beam positive wire by running it to the battery with another wire. If that does nothing then maybe it's your bulb. If it fixes the problem then look at the positive wire back to the handlebar switch and on to the battery. If the high and low are both dim then you might try bypassing your ground wire. |

|

|

|

Post by scooter on Mar 19, 2015 17:11:39 GMT -5

Not sure what is causing this issue. I went for a ride last night and noticed my headlight was USELESS on a street that had no street lights. I also noticed when I would use my brake the headlight would dim to pretty much nothing but the brake light would be bright. The bulb angle is perfect, and when I use the passing light (high beam powered by battery) it shines nice and bright like how it used to when running before this issue came up. The power from the stator appears to be good, power from the battery obviously good. The power to the dash also seems to dim when I hit the brake as well. Maybe a loose wire, but which wire would be responsible for the power going to the headlights and the brake lights and wouldn't dim both? Is there a ground wire that leads up front from the battery? I had a bad ground. It wasn't visible in the wire but the meter said voltage was low. When I changed the wire, it worked great. |

|

|

|

Post by scooter on Mar 19, 2015 17:07:41 GMT -5

So I've had my Super 8 150 for about 6 months and I'm realizing that I should've gone bigger. I love riding, but it is kinda frustrating not being able to get on the highway at all. Or struggling to keep up with traffic when the speed limit is 50 and there's a headwind or a hill. I really don't want to make the same mistake and get something too small, but I'm not sure how big I want to go. Most of my riding is in the city, and I don't want to lose the great maneuverability of my 150 for speed I'm not going to use that often. I would like to take it on the highway with no problems but I don't know if I need something that's going to go over 100mph (I've never even wanted to drive any of my cars that fast). I am concerned that if I get something that tops out around 80, that I'm going to wish I had gone bigger just so I could cruise at that speed and not feel like I am running my scooter into the ground. I just started looking but I've found a 2006 Piaggio BV250 for $2000 (http://washingtondc.craigslist.org/mld/mcy/4906375293.html) with only 700 miles and a 2009 Yamaha Majesty YP400 for $3800 with 2700 miles (http://baltimore.craigslist.org/mcy/4930233427.html). I'm hoping one of you guys could give some insight on if I should even consider moving from a 150 to a 250. Or if I should just look at 300's and above. The 150's mostly max out at 60. I have a helix clone 250 and 75 MPH is about max. I cruise at 60 fine. If you want to cruise at 80, I'd go bigger. |

|

|

|

Post by scooter on Mar 19, 2015 15:42:09 GMT -5

Scoot! This is actually becomming an interesting conversation! 1. The original intent was to characterize the HARDWARE since geh found that there are so many counterfiets out there, even among good retailers, it's become hard to know what we are getting. That is a DIFFERENT subject from how an individual properly TUNES the hardware he has bought. 2. Measuring the "inner distance", etc., are a little complicated. Inner distance: the very inner few mm of the variator are flat, not sloped. The "innder dead zone" is mostly here. Then there is the long part of the face that is slanted (but, to my surprize, a constant angle - the cut of the face is NOT a compound, curved cut - simply flat at an angle --- try a straight edge to check). Then, finally, the outer dead zone - which is part of the same sloped face at the same angle To measure the inner dead zone you need to first put a boss in and measure from it's edge. The hole in the middle of the variator isn't the same, as the bushing inside is not flush with the hole in the variator. You then have to triangulate a little because that measurement is on the flat, not on the same plane as the long, belt-riding angled surface. THEN you have the actual distance from the boss, on an angle, to the outer edge of the inner dead zone. ON THE ANGLE OF THE CUT FACE, not on the flat. Then from there out, on the same angle, you can measure the usable distance and the outer dead zone. These all added up will not equal the measured diameter of the variator since THAT is taken "on the flat" - the SLOPED distance is longer. 3. Performance, like you say, includes a bunch of other things like shims (and other variator set up issues), the clutch, gearing, rider weight, etc. That's a GREAT topic for a second writeup. The only one IU could find here was one from Alley that was really not all that bad - pretty good - but far from enough, not covering half of what you just mentioned. Maybe consider tackling that topic? I'd be glad to go in depth on variators. They are my favorite part of the scooters. I was trying to express how complicated the shapes are, especially the ramps, and how the ramps, back plate, weights, boss length, and other measurements interact, so that it's difficult to examine any one part alone to figure out which one is "best". To measure the inner diameter, lay your calipers across the pulley from inside mark to inside mark. No need to worry about the angle. The view on the left side of the picture below shows the best way to measure. The view on the right is just for clarity. Same for the outside marks. The outside minus the inside diameters will give us the belt travel, tell us what your lowest gear is, what your highest gear is, and if you also include measurements of the OD and the face ID, not the flat part, we can then tell how much we can gear up or down with shims, or by cutting the boss, or even the pulley for that matter. This way you can get a real comparison between the three variators and also find out if you can make the other two perform as well or better than your OEM. For my own analysis, I'd be grateful if you'd throw in those inner mark diameters so I can continue studying the variators you have. That's very cool of you to post all of that. (btw I have considered making the face a different angle because the belt mfg said they can be X amount of angle from nominal. That could be useful. A compound angle would be cool but may wear the belt out by flexing it from one angle to another over and over again.) Thanks RCQ.  |

|

|

|

Post by scooter on Mar 19, 2015 15:16:48 GMT -5

GEH and i were talking clutches and he asked about how the belt was riding in the clutch. So, it just so happened that I took a few pix of the belt yesterday morning:   (that one was with el cheapo installed (note the large "dead zone"), before putting the Dr pulley back on). So last night, returning home from church. Admittedly riding the poor thing hard - faster than it has gone before and really running like a little banshee .... then, all of a sudden "pop" and no power. Engine rev'ed but ... nothing. Knew immediately the belt had popped. Pushed the scooter the last mile or two (getting O L D !), then took a look first thing this morning. Powerlink was pretty new. But what a mess !  With strands stuck down in the clutch and variator:   This is my first belt pop, so I'm not sure what to make of it. Fortunately kept the old bando, so back running again till a new belt comes in. But is it normal that the shredded strands would be so twined down into the clutch? Should I think maybe I have a clutch problem going on? Or is this just par for the scooter course? These variators get too hot. I have lost two belts and they shredded into mulch and stings. I read the break in procedure when I bought my next gates belt. No hard throttling or high speed runs for the first few miles. I don't remember how many, 10 or 30 miles or something like that. |

|

|

|

Post by scooter on Mar 19, 2015 4:51:55 GMT -5

Rcq is doing a great job with his research ! I only have a cell phone for internet right now so I'm really glad he is doing this . I now believe its probably best to buy all CVT and engine parts from PR. Scooter racing is very big down there and they would never use this junk being sold in the US. Many of these so called koso variators come with gouges , nicks and scratches all over the variator face. The DLH variator uses the same back plate with the same type print , checkered flag and coating. I would not be surprised if they are exactly the same all round. The shops in PR have a reputation to uphold and a quality good enough to supply the professional racers. The place I usually order from down there didn't even have these cheap Koso's when I checked. They had a few good looking variators from $40-$60 and some a little higher. They even have a black 117mm variator that I would like to try out. All the variator I looked at aren't as thick at the center where the boss inserts "just like my first koso" . I will soon order a new one and will have to post the results " performance wise " I have a feeling this thread will be active for a long time. I agree he's doing well and it should be a focus for us. A couple of things I will add is that the "ramp depth" is not a good way to measure. The weights don't ride on the hub. Making it longer just reduces the travel, but it's a non issue because all that matters is that the back plate ramps are touching the weights. That means that the longer you make the hub, the thicker the front of the variator needs to be. The proper way to measure the effectiveness of the ramps is to measure the plate ramps, rollers, boss, variator pulleys, clutch shift angle (that curved hole in the clutch hub), and clutch main spring, as one unit, along with the engine. Even then, as we have all seen, the system can be so highly geared that it becomes poorer in performance, because what good are higher gears if you can't pull the load? That's why we've had to reduce our weights so much on some of these variators. Even then we may not have the power to reach maximum rpms. That's why it's nice that the Dr Pulley variator came with shims, so the rider can reduce gearing if need be. It's hard to nail this stuff down for all scooters because rider weight and riding style are factors too. My preference would be a variator that goes all the way down into the pulley, for best off the line acceleration, keeping the rpms at maximum torque and power, making the belt go just high enough that I can still reach max rpm. That may mean a variator that actually never closes all the way. Let's say you change the cam and give yourself more power at certain rpms. Now your variator needs to match that. The ramp "depth" depends on the diameter of the variator. The larger the diameter, the more distance the pulley must move in and out. If the belt is 120mm wide, then you want the pulley faces, at the bottom and at the top, to be roughly 120mm apart so that the belt can travel the entire face of the variator, or close to it. The easiest way to test a variator's travel is to assemble it and mark it and run it. Then you'll have your two diameters. RCQ talked about travel. Travel is not the distance from the ends, it is the distance between the two marks. On the DP variator the travel is: (114.7 - (3.56*2))-(3.76*2)=(107.58-7.52)=100.06mm /2=50.03mm per side (But this assumes that the pulleys are all made the same. That's why knowing the actual diameter at the bottom is important, not the "dead zone".) We already know this is not going to be accurate but let's continue. On the OEM the travel is: (107.4-(3.96*2))-(4.14*2)=(99.48-8.28)=91.2mm /2=45.6mm per side And on the EC the travel is: (115.2-(5.94*2))-(4.57*2)=(103.32-9.14)=94.18mm /2=47.09mm per side I see those numbers don't match RCQ's so one of us goofed, but again, you need the inner mark diameter to know the real travel. The good news, assuming the variators are all cut at the exact same angle, is that he can directly measure the distance between the two marks for a comparison. He can get the real travel by measuring the outer mark diameter and subtracting the inner diameter. The other difference is gearing. The outer marks show us which pulley has the highest gear. That would be the DP at 100.6, the EC at 94.18, and the OEM at 91.2mm. That's 4.7mm per side difference between his OEM and the DP. I think he could add 2.35mm or about .094" of shim to make the gearing the same at top end. He has 3.76mm of inner dead zone, but he could only add 1.88mm or .075" of shim before his belt hits the bottom of the variator face. Don't hold me to that. As I recall, at 30 degrees pulley, you get about 2mm drop for every 1mm of shim. If those numbers are correct, then he could drop the belt to the bottom of the variator face and his top end would be 46.54mm - 45.6mm = .94mm higher than the OEM. So he'd get a higher top speed with the DP if his engine can pull it, and we need the actual inner mark diameter to see how it would affect the low end gearing compared to the other pulley. In other words, he needs to dump his travel figures and use the diameters to get the true travel, then he can figure out how shims would affect performance on the high and the low end. We already know he can get more top end with the DP, but now we need to know what the low end will be, and we need the inner mark diameters to find out. Good work RCQ! You too Geh! |

|

|

|

Post by scooter on Mar 18, 2015 16:06:33 GMT -5

I have an air impact wrench that I never use. One of these days I should since I know it would make removing the variator, clutch & rear axle nuts quicker and much easier. BUT! I would not use it to tighten those nuts. I do have torque wrenches and use them. Doing repairs while out on the road could be complicated by not being able to remove an accidentally over tightened nut. And I have replaced a drive belt on one of my Reflex scooters while on a trip for camping in the Catskill Mountains of NY that required the removal of both the variator and clutch. (needed to make sure all the shredded bits were removed) I have always been able to remove nuts that were properly torqued with the wrenches/ratchets/sockets that I brought with me. No such guarantee if a nut were overtightened. I make several long distance rides on my scooters, so I try to make sure I can do repairs myself at the side of the road. That may not be as critical for those riding within easy retrieval distance of home. So whacking it off or thumping it on with an impact wrench might be OK for them. But I don't think I'll risk thread stripping, snapping bolts or being unable to loosen something while traveling..... But that's just me.  I have a 1/2 inch impact that works for the most part. I can tighten the bolts on as hard as it will go and still remove them with my manual variator tool and a socket wrench, but some of the ones from the factory are really super tight and neither of these will get them off. I bought the big 3/4" heavy duty impact and I'll try it out this weekend. Then I'll put the nuts back on with my old 1/2" impact. |

|

|

|

Post by scooter on Mar 18, 2015 15:43:55 GMT -5

Did you see how I measured the center of the 2 Koso's ? From front to back , where the boss goes. Are you saying they are all the same ? When it comes to width , that's what I'm talking about . you may have understood me , I'm just trying to get a good picture of all of these variators. SOME VERY INTERESTING MEASUREMENTS, I THINK. Here is a diagram so we are all talking about the same things:  So here are the comparisons ................................................... OEM....................... Dr. Pulley ............... el Cheapo1. Overall sizes E: Diameter .......................... 107.4mm ................. 114.7mm .............. 115.2mm H: Thickness ......................... 35.7mm .................. 35.6mm .............. 35.7mm D: Boss diameter ................. 24mm .......................24mm ................ 24mm The thickness of all three is the same. 2. Belt Travel DistanceOne of the most important things is the overall distance on the face of the variator over which the belt can travel. Of course this is influenced by the overall size of the variator (107mm or 115mm). But it's also changed by the two 'dead zones' - one at the center of the variator (belt cannot drop lower than this) and one at the edge of the variator (belt cannot rise higher than this). Here are the interesting results: ................................................... OEM...................... Dr. Pulley ............... el CheapoC: Inner Dead Zone .................. 4.14mm ................. 3.76mm .................. 4.57mm A: Outer Dead Zone .................. 3.96mm ................. 3.56mm .................. 5.94mm Thus, the USABLE BELT TRAVEL DISTANCE IS (each side): B: ...........................................35.13mm ................39.54mm ............... 36.77mm

This is important because it gives you the most "gears" when the usable distance is longer. This can be used to give you more low end or more high end.

The USABLE belt distance of the 115mm el Cheapo is only slightly better than the smaller, 107mm OEM variator !!!!!!!! The thing here is the diameter. Getting the belt out to 115mm will give you more top end speed than the 107.

107 - 3.96*2=99.08 and

115 - 5.94*2=103.12.

If you shave the face of the boss or sheave a little, you could go all the way out to the edge, and if you put in shims, you could go all the way down until your belt hit the boss. These are extremes of course and not desirable. For top speed, IF your motor can push it, the oem is inferior, the el cheapo is much better, and the DP wins over the EC.

We already know the DP and the EC can give more top end. Without cutting or shimming, we see the DP has the smallest lower end dead zone, BUT what we really need to know is the diameter where the inner dead zone begins. The smallest diameter will give us the lowest starting "gear".3. RAMP SIZEThe depth of the ramps (at the hub) are not all the same, and the "length" of the ramp (distance from hub to outer extremity of the ramp are also not the same. The depth depends on how thin the variator is at the hub. The lengthdepends on how thin the VERTICAL EDGE is on at the outer edge of the ramp. A deeper ramp (at the hub) allows for more dramatic movement of the sliders/rollers. The length of the ramp does the same. So here are the measurements: ................................................... OEM....................... Dr. Pulley ............... el CheapoG: Ramp Depth (at hub) ........... 30.2mm .................. 29.37mm ................ 28.58mm I: Ramp length (hub to edge) .... 26.99mm ................. 31.57mm ................ 29.27mm The OEM has a nice, deep cut ramp - but of course it's short (since the thing is only 107mm diameter). el Cheapo is both cut not as deep and is not as long (because the side wall of the variator is thicker). It's a loser on BOTH counts. This is where it gets complicated. This is a calculus problem. We need to know the rpm at any given point on the pulley face. You have w weight at x diameter traveling at y rpm on z ramp angle, but that only tells us how much force the rollers will exert on the movable pulley. What also matters is what the engine needs, and what you want. It needs the belt to rise when it reaches the rpm that you decide it needs to move at, at any given speed, on a given road incline, and the way you want it to.

In my case, I wanted my engine to accelerate at 6,500 rpm when at WOT and to attain 7,500 rpm, with the belt all the way out, on level ground. If the ramp is too steep then the pulley will start to open at cruising rpm, resulting in high rpm cruising. If it is shallow then it may make the pulley close too soon as you take off, bringing your rpms to below what you want, resulting in poor acceleration.

The perfect variator would give you whatever rpm you want, at any speed, and also the maximum top end that your motor can pull at max HP, and a low cruising rpm. In other words it would be electronically controlled and adjustable on the fly for various driving styles and road conditions. The next best thing is a variator ramp that is tuned to your engine, bike, weight, and driving style.4. VARIATOR WEIGHTI'm with you on this. It's probably not a big deal.

Also don't forget that your back plate also has a width and a ramp angle which will affect performance. The rollers will be riding on the two ramps.

This also brings up sliders whose dimensions change depending on what angle they are at. That's a big deal and makes the math more intense.Anyway, there is the detailed comparison. Thanks, geh, for the motivation to look into this. It's odd we all have been flying blind about variators for so long. So, this is a start. Maybe others can add to the library so we can know what is really good or bad. |

|