New Rider

Currently Offline

Posts: 41

Likes: 1

Joined: Dec 16, 2013 19:00:05 GMT -5

|

Post by sk8almost44 on Dec 16, 2013 19:11:14 GMT -5

Hello! I use to use the old forms until they shut down! I use to own a 50cc and now I finally moved up to a 150cc .

Anyways Ive came for multiple things today.

1. My 150 scooter (Chinese GY6) was bought on Craigslist for $350. Cleaned the carb and started right up! Everything is bone stock from the spark plug, the hoses valves haven't been adjusted, etc. I'm not sure what maintenance the previous owners have done prior. I do know it sat for 3-4 months. Also the kickstart does NOT work at all.. It rotates, but sticks once it's been kicked and doesn't sound too good..

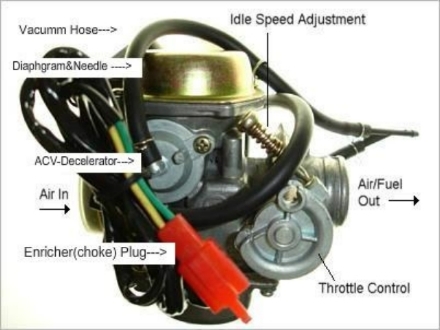

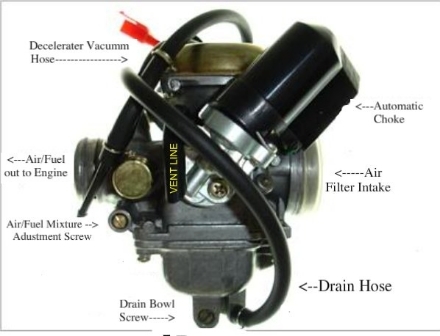

Anyways, It starts right up but the idle is very high (4k RPM) even after letting it run for 10 minutes. The idle screw is all the way out, and the A/F screw is screwed all the way in. Maybe too much air from somewhere (air leak?)? The wheel is rotating ofcourse. It could be the clutch? I don't notice the clutch sticking when I roll the scooter backwards and the RPMs dont lower when the wheel touches the ground.. I'm beat, so any ideas would greatly help!

2. Gas gauge doesn't work, says empty tank. What should I look for or how can I troubleshoot this?

3. There is a switch on the right-side over by the electric start that switches left to right, or right to left. Has 3 options... What is this switch for? Its not turn signal.. again, on the right-side.. I would ASSUME it's a killswitch, but it does nothing with the engine on. Maybe it is a killswitch but it is not grounded properly? But has 3 options instead of 2.. imageshack.us/a/img855/4047/txcw.jpg imageshack.us/a/img855/4047/txcw.jpg

Thank you for your help in advance!!

|

|

|

|

Post by urbanmadness on Dec 16, 2013 21:53:43 GMT -5

Start with checking the easy stuff. Do you have enough slack in your throttle cable? Also make sure the carb is seated completely into the intake boot. You will have to adjust the A/F mix after that.

Fuel gauge is probably a fuel sending unit.

|

|

|

|

Post by alleyoop on Dec 16, 2013 22:24:36 GMT -5

That switch that has 3 positions is most likely for the lights BUT on some it is a DEAD switch not connected to anything anymore and the lights come on after the motor starts. You cannot turn them off and on.

the other two problems are what urban said, the fuel gauge you will have to take out the sending unit and check if the arm with the float is stuck in the down position or the float does not exist anymore, or the arm is to tight in which case you just have to loosen it up by moving the push on washer out a little.

The throttle cable should have about 1/4 of an inch of FREE PLAY before it actually pulls on the cable and operates the BUTTERFLY. So you should be able to twist the throttle about a 1/4 of an inch and it should not do anything.

Alleyoop

|

|

Sophomore Rider

Currently Offline

Posts: 163

Likes: 15

Joined: Aug 20, 2013 13:54:34 GMT -5

|

Post by phssthpok on Dec 16, 2013 22:37:24 GMT -5

High RPM: My first instinct is to check that the throttle cable is adjusted properly to ensure the throttle blade is being allowed to completely close. Given that the design of the carburetor places the throttle blade behind the main fuel metering apparatus, an air leak in the manifold shouldn't be able to cause a high RPM situation (I'm not sure I'd call 4K rpm an 'idle') especially with the A/F screw bottomed out (which IIRC should completely cut off all fuel through the idle circuit). Check also the automatic enricher servo. If it's stuck in the 'on' position, and you have a vacuum leak in the manifold, it's plausible that such conditions could result in the high 'idle'. It's also 'possible' the vacuum actuated petcock is faulty allowing some fuel to enter the manifold via the vacuum hose. However this too would pretty much require an accompanying vacuum leak in the manifold to supply a viable air/fuel mixture to cause the high RPM condition, otherwise the fuel would most likely flood out the engine causing a stall. From here all I can do is randomly speculate. It's possible the float itself is either malfunctioning or the needle/seat is failing to seal properly. In either case the fuel level could plausibly exceed the limits of the bowl, allowing some to seep into the throat of the carb, and thence be drawn into the intake manifold. If there is indeed an air leak in the manifold it's plausible that a 'perfect storm' of variables such as the above would account for a high 'idle' under the parameters you describe. Note however this is pure speculation. Fuel gauge: My first step would be to check the fuse panel. If the fuse is 'OK', then next I'd apply a multimeter or 'test light' to the wires at the gauge end of the harness to check for voltage, and work my way back from there (Note: I have, in the past, seen a fuse look perfectly fine, yet be faulty...testing a replacement fuse would not be a wasted effort 'just in case'). If you don't have a multimeter, then you could try checking the gauge for function by using some jumper wires directly from the battery to the gauge terminals. If the gauge 'functions' (read: moves) then you may safely presume that the gauge itself is fine, but it's not receiving voltage 'signal' for some reason (I'm presuming the fuse 'checked out'). The next physical thing to check would be the float/sending unit assembly in the fuel tank. Ensure proper mobility (read: make sure it's not seized in one position). If the float arm moves freely then at this point you MUST dig out a multimeter to do any further diagnostics. You will need to set for OHMS and check for variations in the readings at the terminals of the sending unit on top of the tank (where the wires plug in) as the float arm moves up and down. The actual numbers don't matter at first...you are checking to see if there is an electrical short/failure in the sending unit. If there is zero change in the numbers as you move the float arm up and down, then the sending unit is 'bad'. If the sending unit and gauge check out as 'functioning', the fuse is 'OK', and you have made sure all connections are clean and tight, then the only thing left to do is a point-by-point continuity test on the wiring harness from the tank to the gauge. You have my sympathies. (I HATE tracing electrical faults!) Mystery switch: Looks like a three position headlight/kill switch. Probably disconnected/bypassed by the previous owner. (which leads me to believe the fuel gauge issue may be related by similar circumstances) |

|

|

|

Post by skuttadawg on Dec 16, 2013 23:31:01 GMT -5

My Echarm got to were it idled so high they would would spin . Having EFI I do not have an idle screw . I rerouted the cable since it was binding and it was good again . With EFI the ECU controls idle .

Ground the lead from the float to the frame . If the needle bounces it is the gauge , if it goes to full it may be the send ing unit or at least a short in the circuit . My @t the gauge is dead on it but my Echarm says it is empty at half a tank

|

|

Freshman Rider

Currently Offline

Posts: 86

Likes: 7

Joined: Mar 17, 2013 21:08:40 GMT -5

|

Post by korn858 on Dec 17, 2013 12:44:54 GMT -5

I just ordered my third fuel sending unit. ($13 shipped on Ebay). The floats on these keep falling off. I'd check that first.

|

|

New Rider

Currently Offline

Posts: 41

Likes: 1

Joined: Dec 16, 2013 19:00:05 GMT -5

|

Post by sk8almost44 on Dec 17, 2013 19:39:30 GMT -5

Thank you everyone for your input! Sorry I forgot to mention I already checked the throttle cable, infact my throttle handle is completely off and disconnected as you can see in the 3rd picture. Just to double check, I went next to the carb and pulled a little on the cable between the carb and the arm that pulls the cable, and there is the correct amount of slack with no tension. So it's not the cable unfortunately  I have recorded a video! Maybe my carb isn't properly connected back together? I installed new blue hoses to get rid of the stock hoses (well, most of them. Haven't done the gas hoses yet). Also as I said before, the kickstart doesnt want to work. I also made a video. I can open the crankcase and take pictures/videos, just some input before I unscrew all the bolts. By the way there is no rust on this scoooter, it was garage kept! AND PLEASE, if you need anymore pictures/videos of anything to help you help me, please let me know!! I will be more than happy to! -on a side note, I will check out the fuel and 3 switch later |

|

New Rider

Currently Offline

Posts: 41

Likes: 1

Joined: Dec 16, 2013 19:00:05 GMT -5

|

Post by sk8almost44 on Dec 17, 2013 19:45:08 GMT -5

I got lost after this. Could you please explain on how to do this? High RPM: Check also the automatic enricher servo. If it's stuck in the 'on' position, and you have a vacuum leak in the manifold, it's plausible that such conditions could result in the high 'idle'. It's also 'possible' the vacuum actuated petcock is faulty allowing some fuel to enter the manifold via the vacuum hose. However this too would pretty much require an accompanying vacuum leak in the manifold to supply a viable air/fuel mixture to cause the high RPM condition, otherwise the fuel would most likely flood out the engine causing a stall. |

|

|

|

Post by tvnacman on Dec 17, 2013 19:57:28 GMT -5

when you turn the key switch does the fuel gauge move at all ?

I would open the cvt it sounds like its gunked up .

I wonder if you got the needle back in correct ?

John

|

|

New Rider

Currently Offline

Posts: 41

Likes: 1

Joined: Dec 16, 2013 19:00:05 GMT -5

|

Post by sk8almost44 on Dec 17, 2013 20:42:06 GMT -5

when you turn the key switch does the fuel gauge move at all ? I would open the cvt it sounds like its gunked up . I wonder if you got the needle back in correct ? John No it does not move at all. I do not know how to access the gauge inside the gas take I just spent an hour tearing plastics off and still can't find it.. and the CVT isn't gunked up I just had it opened 2 days ago. No rust either. and the needle inside the carb? like the jets? I can take it back apart again tomorrow and double check.. Thank you |

|

|

|

Post by tvnacman on Dec 17, 2013 20:50:45 GMT -5

the needle that is attached to the slide and diaphragm , when you reinstall it, it slides into the main jet . the kick start spindle has lube spots , where the shaft comes through the cvt cover and bushing , then where the other end pivits in the case there is another bushing . The spindle gear and the rear pulley gears must be lined up and the spindle spring needs to be seated correctly . You will pull your hair out till you see and understand it (been there done that) . Someone please come up with a picture labeled so he can see what I'm talking about . John thescooterprofessor.proboards.com/thread/3270/gy-6-kickstart-gear-alignment |

|

Sophomore Rider

Currently Offline

Posts: 163

Likes: 15

Joined: Aug 20, 2013 13:54:34 GMT -5

|

Post by phssthpok on Dec 17, 2013 21:17:18 GMT -5

I got lost after this. Could you please explain on how to do this? High RPM: Check also the automatic enricher servo. If it's stuck in the 'on' position, and you have a vacuum leak in the manifold, it's plausible that such conditions could result in the high 'idle'. The auto-enrich servo is similar to an electric choke only rather than cutting off air flow ahead of the venturi (or fuel metering jets in this case) like on a car, it opens a fuel passage to allow extra fuel into the manifold BEHIND the throttle blade, to aid in cold running conditions. It is located on the drive-belt side of the carburetor, and usually has a somewhat shiny back plastic cover on it with a couple of wires coming out. This is an electric 'plunger' servo, that should shut off (retract) when the engine reaches operating temperature. If this is faulty, then the servo remains 'engaged' and constantly adding extra fuel. Under normal conditions this would result in idling problems as the engine 'floods out'. You would need to have a corresponding vacuum leak for this condition to result in sustained high RPM. The vacuum actuated petcock is essentially a 'dash pot' assembly used to open and close a fuel flow valve. When vacuum is applied to one side of the diaphragm, the valve on the other side of the diaphragm is opened allowing fuel to flow (a weak spring is used to press on the diaphragm and keep the valve closed when there is not enough vacuum present). If the diaphragm fails, then fuel could (probably would) be sucked past the diaphragm into the vacuum line, and then on down to the manifold where, again, you'd need a corresponding vacuum leak to supply enough air for sustained operation lest the engine flood out. |

|

|

|

Post by tvnacman on Dec 17, 2013 21:34:02 GMT -5

I got lost after this. Could you please explain on how to do this? The auto-enrich servo is similar to an electric choke only rather than cutting off air flow ahead of the venturi (or fuel metering jets in this case) like on a car, it opens a fuel passage to allow extra fuel into the manifold BEHIND the throttle blade, to aid in cold running conditions. It is located on the drive-belt side of the carburetor, and usually has a somewhat shiny back plastic cover on it with a couple of wires coming out. This is an electric 'plunger' servo, that should shut off (retract) when the engine reaches operating temperature. If this is faulty, then the servo remains 'engaged' and constantly adding extra fuel. Under normal conditions this would result in idling problems as the engine 'floods out'. You would need to have a corresponding vacuum leak for this condition to result in sustained high RPM. The vacuum actuated petcock is essentially a 'dash pot' assembly used to open and close a fuel flow valve. When vacuum is applied to one side of the diaphragm, the valve on the other side of the diaphragm is opened allowing fuel to flow (a weak spring is used to press on the diaphragm and keep the valve closed when there is not enough vacuum present). If the diaphragm fails, then fuel could (probably would) be sucked past the diaphragm into the vacuum line, and then on down to the manifold where, again, you'd need a corresponding vacuum leak to supply enough air for sustained operation lest the engine flood out. here is another good video thescooterprofessor.proboards.com/thread/575/alleys-autochoke-demoJohn |

|

|

|

Post by alleyoop on Dec 17, 2013 21:40:12 GMT -5

The Enricher by DEFAULT is RETRACTED WHEN COLD. IN the Retracted position it feeds extra fuel for cold starts. Once the motor starts it then FEEDS voltage to the ENRICHER and melts the GEL inside and pushs the CYLINDER out to shut off the EXTRA fuel. It fully EXTENDS out to shut off the extra fuel within 3-5 minutes and it stays EXTENDED as long as the motor is running. Once you shut the motor off no more voltage is being sent to the enricher and it starts to RETRACT back as it COOLS OFF ready for the next cold start. Question: Right now is the IDLE SPEED SCREW backed out? Turn the IDLE SPEED SCREW counter clockwise and see if the IDLE goes down. Take a Video on the THROTTLE SIDE of the CARB and Video by the THROTTLE CABLE on the CARB when you just twist the throttle a little . Want to see how the Throttle Control wheel and cable are working. Alleyoop   |

|

New Rider

Currently Offline

Posts: 41

Likes: 1

Joined: Dec 16, 2013 19:00:05 GMT -5

|

Post by sk8almost44 on Dec 17, 2013 21:49:47 GMT -5

The Enricher by DEFAULT is RETRACTED WHEN COLD. IN the Retracted position it feeds extra fuel for cold starts. Once the motor starts it then FEEDS voltage to the ENRICHER and melts the GEL inside and pushs the CYLINDER out to shut off the EXTRA fuel. It fully EXTENDS out to shut off the extra fuel within 3-5 minutes and it stays EXTENDED as long as the motor is running. Once you shut the motor off no more voltage is being sent to the enricher and it starts to RETRACT back as it COOLS OFF ready for the next cold start. Question: Right now is the IDLE SPEED SCREW backed out? Turn the IDLE SPEED SCREW counter clockwise and see if the IDLE goes down. Take a Video on the THROTTLE SIDE of the CARB and Video by the THROTTLE CABLE on the CARB when you just twist the throttle a little . Want to see how the Throttle Control wheel and cable are working. Alleyoop  ooohhh the enricher... I can see if it's working or not I can find out tomorrow. I never thought about it being that. And the idle screw is not touching the medal accelerate pad (it's turned counter clockwise). I will take all the plastics off and get a good video of the carb tomorrow! |

|