|

|

Post by jeepsteve92xj on Aug 25, 2013 9:51:54 GMT -5

I popped off the CVT cover from the Znen. s235.photobucket.com/user/jeepsteve92xj/library/scooter/ZNEN/Znen-CVTFound a few chips - I don't recall seeing any when I've had the cover off before. There is a small slot where chips could fall out. I'd bet some chips were ground to dust in the clutch. The chips seem to be from a casing around the lobes of the clutch. I sanded down the inside of the bell to take the glazing off, and took a file to the clutch material to de-glaze. Reinstalled the variator with 13g rollers (Had 12g sliders) I didn't get to get a top speed run. But for sure the clutch was smoother, not nearly as grabby as it has been. |

|

|

|

Post by tvnacman on Aug 25, 2013 10:58:38 GMT -5

I think you have the grams mixed up . If its all good great . I was waiting for your post .

John

|

|

|

|

Post by jeepsteve92xj on Aug 25, 2013 11:23:23 GMT -5

No, I had only one set in at a time: - originally the 17g, then 9.5 or 10g sliders, then 12g sliders, and now 13g rollers.

I finally took the clutch off to have a look on why it was grabby, even at 1600rpm idle.

I never noticed the chips before, but there must have been some that escaped or were also ground to dust. There is too much missing material for it to be recent (since the NYC variator with 12g sliders install).

I had the clutch off the Xingyue but didnt see anything like this. I am not sure if the stacks of plates were naked or encased. I will have a look again when I install the 13g sliders.

I don't know of my pictures show it, but the V pulley on the clutch looks fairly unused, like the belt isnt pulling deep. Maybe it just wont show the used area like the variator pulleys do. If I get back in there soon, I will mark that pulley to see how far the belt travels.

|

|

|

|

Post by pmatulew on Aug 25, 2013 11:29:44 GMT -5

Isn't that interesting! I was`expecting to see the clutch shoes had come off.

I wonder why they bother encasing the clutch arms in potmetal? Certainly the stamped and riveted steel plates are taking all the load. I've got a couple sets of pliers that are made out of steel plates like that. Cookie cutter steel plate is much cheaper to manufacture than casting or forging.

If anything that actually makes me feel better about how the clutches are constructed knowing that there is something solid in there.

|

|

|

|

Post by jeepsteve92xj on Aug 25, 2013 11:36:40 GMT -5

I didn't expect that either. Extra weight? Or less weight after shedding some material, in this case.

I have a pair of the Craftsman pliers like that - Broke them on the first use and haven't ever had them handy when I'm going near Sears. Bet they've been broken for nearly 18 years now.

|

|

|

|

Post by ltdhpp on Aug 25, 2013 17:14:11 GMT -5

Please replace that clutch and bell ASAP - the clutch friction material is attached to that pot metal that is crumbling off the arms... you can see it clearly starting to come up in several of the pics.

|

|

|

|

Post by geh3333 on Aug 25, 2013 23:57:12 GMT -5

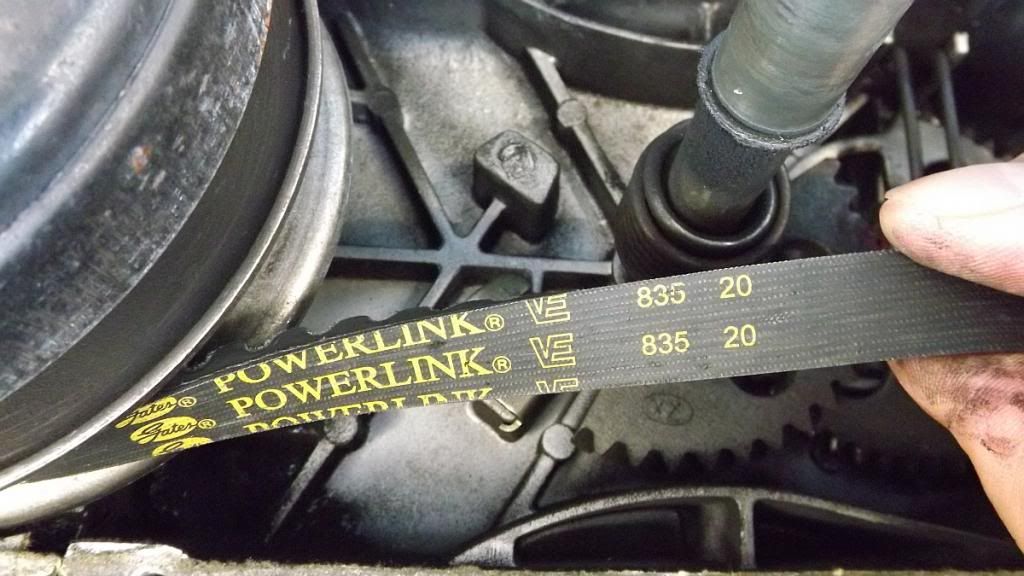

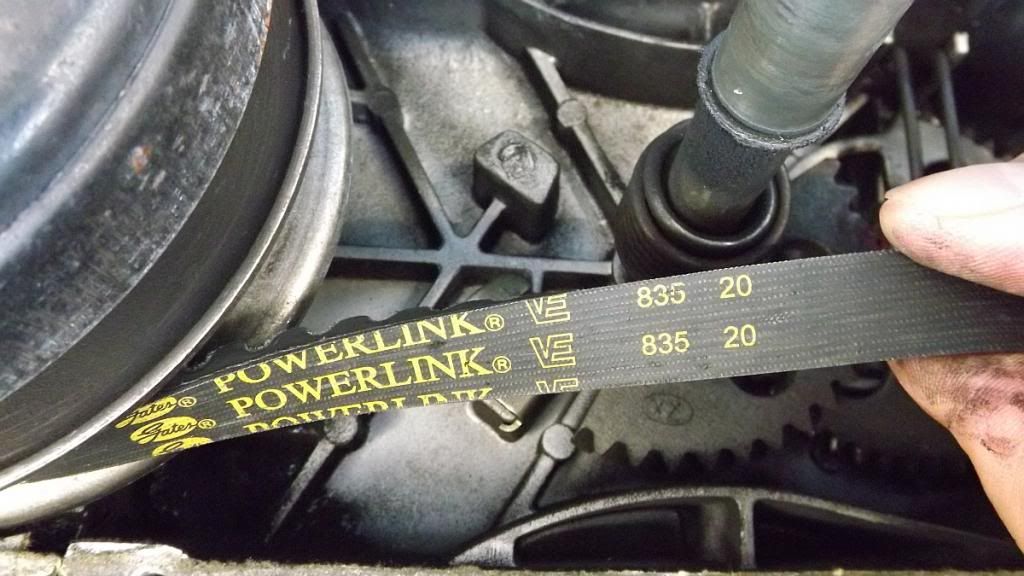

Def replace the clutch before you star getting nicks in the variator from the debris. Also looks like you ar not getting full use of the variator . You hav a lot of unused space left. What size belt do you use ?

|

|

|

|

Post by rockynv on Aug 26, 2013 4:36:59 GMT -5

I popped off the CVT cover from the Znen. s235.photobucket.com/user/jeepsteve92xj/library/scooter/ZNEN/Znen-CVTFound a few chips - I don't recall seeing any when I've had the cover off before. There is a small slot where chips could fall out. I'd bet some chips were ground to dust in the clutch. The chips seem to be from a casing around the lobes of the clutch. I sanded down the inside of the bell to take the glazing off, and took a file to the clutch material to de-glaze. Reinstalled the variator with 13g rollers (Had 12g sliders) I didn't get to get a top speed run. But for sure the clutch was smoother, not nearly as grabby as it has been. Yep I have posted about this a number of times. This is what causes much of the vibration that destroys mufflers and the input shaft bearings in the final drive. I finally replaced mine with the standard clutch and bell set from Parts for Scooters. Had to replace the bearing and seals in the gearcase too while I was at it. Make sure you grease the needle bearings that the clutch spin on at engine idle while your in there. |

|

|

|

Post by jeepsteve92xj on Aug 26, 2013 5:55:44 GMT -5

[replyingto=geh3333]geh3333[/replyingto]The belt is 835-20  The bearings and shaft seem to be ok, I added a dab to the needles. for sure, gonna replace that clutch soon. |

|

|

|

Post by geh3333 on Aug 26, 2013 6:10:42 GMT -5

Hav u ever tried an 842 ? U may get some extra climb on the variator

|

|

|

|

Post by jeepsteve92xj on Aug 26, 2013 6:34:25 GMT -5

I haven't tried any other belts yet. I did go to 13g rollers from the 12g sliders, but two rides since Saturday, I was in traffic so 40/45 was as fast I got to go.

I could use the 17G and 11G or 13G (or whatever other weight rollers I have) mix to get a higher average.

|

|

|

|

Post by rockynv on Aug 27, 2013 4:30:55 GMT -5

The belt is 835-20  The bearings and shaft seem to be ok, I added a dab to the needles. for sure, gonna replace that clutch soon. Don't wait too long on the clutch replacement especially if you start getting a buzzing feeling in the floor boards. An out of balance clutch can quickly take out your gear case bearings and input shaft. |

|

|

|

Post by jeepsteve92xj on Aug 27, 2013 5:47:29 GMT -5

New clutch is on the way!

|

|

|

|

Post by tvnacman on Aug 27, 2013 9:30:42 GMT -5

New clutch is on the way! USPS says tomorrow for the clutch . Steve did you get the sliders for the other scooter ? John |

|

|

|

Post by jeepsteve92xj on Aug 27, 2013 9:39:08 GMT -5

I did get the sliders, I did not have a chance to install them yet. Thanks John

|

|