Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 17, 2015 12:41:26 GMT -5

Update: Good news, i assembled the engine and it started. Engine is working.  Here are some pictures from during the rebuild: The engine is out of the frame:  The variator side:  Taking out the megneto using a puller:  The stator:  Revealing the starter clutch. I used the special socket to remove it. It's a reverse thread nut.  The right cover that goes over the starter clutch:  The engine head after removing the head bolts and nuts:  The head after rocker arms and camshaft removed:  Now you can see the cylinder and piston:  The old piston:  The old cylinder:  The engine head before replacing valves, springs and valves oil seals:  Engine Head after doing valves lapping:  I did a water test to the head, to see if there is a leak from the new valves. (sorry the picture came out unfocused):  After removing the starter clutch:  The right crankcase:  I replaced the crank bearings, including the connecting rod needle bearing. (I'm not sure if this picture is before or after replacing the bearings)  The right crankcase is installed with a new gasket and the starter clutch:  The cover is installed over the starter clutch and the stator is installed:  The new piston installed on the connecting rod, and a new gasket:  The new cylinder installed:  The engine head on the cylinder:  I also replaced the timing chain and the chain tensioner. The gear after removing bearings:  I used this puller set to remove the bearings:  Gear after installing new bearings. i also replaced the bearing on the driving gear.  Gear cover after installing new bearings and oil seal:  New oil seal on the driving gear from the variator side:  Ofcourse i also replaced the crankshaft oil seals. I started the engine, and it's working.  I do have a question about tuning the carburetor. When you pull the throttle quickly and then release it, the rpm goes down more than it should and after a few seconds goes back to the correct idle. Is that mean i have lean or rich mixture? Thank you all for helping me during this rebuild. :-) |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 14, 2015 2:46:23 GMT -5

Is it also important not to have gaps over the piston pin?

Also, regarding the pin circlips, is it important where to have their gaps?

do you need to put the gap up, down, or is doesn't matter?

|

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 13, 2015 20:01:31 GMT -5

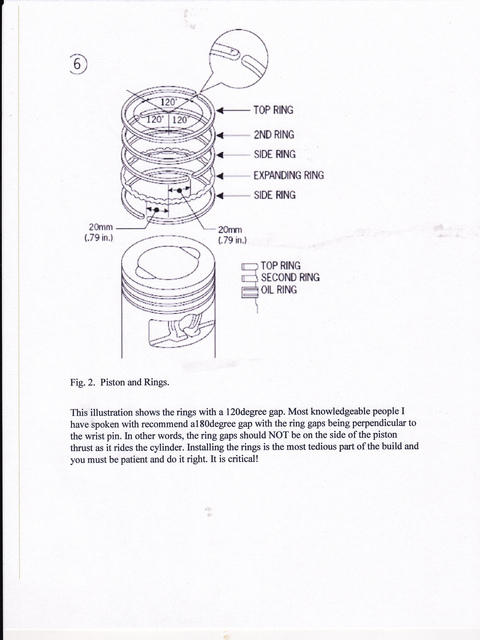

Yes, that is a good video. Only thing I do different is clock the oil rings 120* apart from each other, I don't like the idea of the gaps being so close. One hint, this guy had no problems getting the piston and rings into the jug, it's not that easy when it's all installed in the engine. I use a hose clamp to compress the rings, put the top of the piston into the jug, then tap the jug down forcing the hose clamp off as the rings slide into the jug. No cuts on your fingers with this method. Do you mean the 3 bottom rings (the spring with the 2 oil rings) ? I thought you need to put the oil rings gap 20mm on each side of the spring gap. it's not supposed to be like in this picture?  |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 13, 2015 12:19:28 GMT -5

I wanted to ask regarding the piston rings installation.

I found a video on youtube that explain how to do it.

Is this the correct way?

Thank you.

|

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 10, 2015 18:54:00 GMT -5

Thank you for the advice.

At the end i tightened them until it felt tight enough.

I hope to post more pictures very soon.

|

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 8, 2015 3:50:54 GMT -5

Hi, Just an update and also a question. The new valves arrived and i installed them, also did valve lapping. and i also replaced the springs. I was starting to assemble the engine, put the crankshaft inside (used heat & cold method), and then i went on tightening the right case. it has 2 M6 bolts.  The manual i have said to torque it to 1.5-20 kgf-m (around 15-20 Nm). So i torque it to 15Nm and one of the bolts started to break, and the other was on his way to break too.  Luckily i was able to pull them out and the threads inside the case are ok. After when searching in google i found a chart saying that M6 bolts in aluminum needs around 5 ft/lb (around 7Nm). What do you think is the correct torque for the M6 bolts? There are also the 2 M6 bolts on the left side of the engine head (where the timing) . What is the correct torque for them? The manual is saying 1.0-1.4 kgf-m (around 10-14 Nm). Is it too much? |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 6, 2015 15:48:21 GMT -5

The cover went back very easy, and when i rotate the driving shaft, the final drive shaft is moving smoothly.

so i guess it's all okay.

Thank you.

|

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Mar 5, 2015 16:59:40 GMT -5

Hi, As part of rebuilding the engine i replaced the gearbox bearings, and i have some questions and maybe you can help. When i installed 2 of the bearings in the engine block side i noticed that they are not completley aligned with the top end of the bearing seat. The bearing is about 0.5mm higher. but they just will not go inside more. I don't remember how it was before i took the bearings out. Is it supposed to be like that? Here is a picture of the final drive shaft bearing (engine side), and you can see it is out about 0.5mm :  Here is a picture of the driving shaft bearing, also not completley aligned. Btw, before i installed the shaft i put it in the freezer, and heated the engine case with an heat gun. The shaft with the bearing on it just slid in very easily.  Here is the picture of the counter shaft bearing (engine block side), and here you can see it's fully down in the bearing seat.  Before i took out the old bearings, i did noticed that the gears have mark lines on them and that they are aligned with each other. When i put the gears inside after installing the new bearings, the mark lines do align with each other. Does that mean that the bearings are seated ok? Here is a picture of the mark lines on the counter shaft and driving shaft gears (after installing the new bearings). You can see they are aligned.  What do you think? Thank you. |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Jan 31, 2015 11:40:04 GMT -5

New valves are on their way, but i wanted to try and clean the valves with a fine sandpaper. I put the valves in a driver drill, and i used a 150 and 400 grit sandpaper. Huge difference from before the cleaning as you can see from the pictures. I also measured the valves stem again with a more accurate tool, and the intake stem is 4.98mm, and the exhaust is 4.96mm. So these valves are still ok, but i'll use the new ones.   |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Jan 25, 2015 16:47:42 GMT -5

Yes, you are right. I will order new ones.

Though SYM parts are little more expensive.

|

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Jan 25, 2015 9:49:00 GMT -5

I would try a steel brush wheel on a dremel, but your idea for the sandpaper should work. Be sure to wear gloves or hold the paper with pliers. You should change the valve stem seal on the exhaust while you're at it, it's probably pretty worn from those deposits. I'm replacing both of the valves stem seals (intake and exhaust). Before i'm trying to remove the carbon deposits, anyone knows what is the minimal stem diameter for the valves (for a 125cc engine)? My valves stem are around 4.  mm . what is the stem diameter for a new valve? The buckets of Chem dip they sell at auto parts stores and wal-mart may work very well.  Never seen that in stores in my area. (i'm not from the US) |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Jan 24, 2015 4:12:28 GMT -5

Yesterday i worked on the engine head. I took out the valves and removed the valve stem seals. Did some cleaning on the head. Tried to clean the valves, but the carbon deposits on the exhaust valve are really hard to remove. I soaked the valves in a break cleaner fluid over night, and the intake valve is pretty clean, but the exhaust valve still have heavy carbon deposits on it. Is it ok to put the valve into a driver drill and then use a fine sandpaper to clean that carbon deposits? What sandpaper grit should i use? Do you have other ideas? Here is a picture of the head right after removing the valves:  The head after some cleaning:  The valves. (the exhaust valve is on the left)   |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Jan 17, 2015 4:35:21 GMT -5

Thank you, i'll try to soak the gaskets in WD-40 and then remove them.

|

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Jan 16, 2015 12:39:14 GMT -5

Some updates: Finally i had some time, so i did a few things. First of all, i removed that crank oil seal. I used the "oil seal remover tool" . All i had to do is pull it a little, and the oil seal started to move. Then i was able to just push it out with my fingers. Btw, i pulled it out from the variator side. The removed oil seal and where it was:   My rear shock bushing was completely destroyed, so i had to replace it. You need to use some kind of bushing remover. The rear bushing is 20mm, so my father machined this puller:  This is how i used it:  And this is the old bushing:  I also took the crankshaft to a place where they replaced the bearings, including the connecting rod bearing. I have a question on how to remove the old gaskets? On some of the parts, there are gaksets pieces that are stuck. How do you remove these without damaging the surfaces? |

|

Sophomore Rider

Currently Offline

Posts: 128

Likes: 3

Joined: Jun 1, 2013 5:11:09 GMT -5

|

Post by gingel on Dec 30, 2014 7:15:28 GMT -5

Don't you supposed to pull it from the variator side? Anyway, it doesn't move either way. This engine did around 115,000 KM without ever opening it. I actually didn't have time to try with the WD-40 like alleyoop said. Looks like quite a job! I'll be interested to see how it pans out. Were the parts expensive for the rebuild? Cheers!  Thank you, hopefully i will be able to assemble everything back together. I ordered all genuine SYM parts, so it's a little more expensive. |

|