|

|

Post by rdhood on Feb 22, 2015 20:21:32 GMT -5

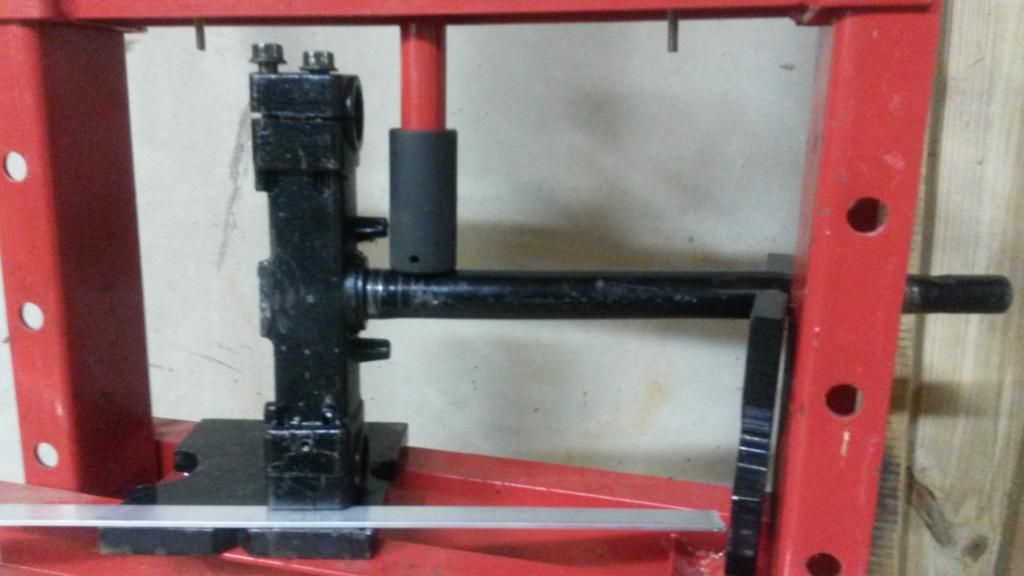

Remember my triple tree. It caused this:  You can imagine the bend in the tt. Well, I ordered a new triple tree that is dimensionally really really close, but it is still going to take some chinese modification strategies to make it work. Yuk. Being prepared to do that, I started eyeing the bent triple tree that I took off. I noticed that it is actually bent in the steerer. I imagine that the steerer bearing got loose, dude hit something and bent the steerer about 1.5" up from the top of the base of the triple tree. Having nothing left to lose, I decided to see if I could straighten it. Now, before you think I am crazy, I have bent my fair share of metal. I have even straightened a rifle barrel. In that case, the rifling in an unfocused look down the barrel formed concentric rings. I had two other rifles for comparison, and I managed to do a very very good job. It is similar to collimating a telescope using the diffraction rings around a light source. Any way, I was pretty successful at that, so what did I have to lose on the triple tree? The trick to this, btw, is to pick that correct place to press and to properly support the ends. The metal rod will have some spring to it, so you bend it JUST past center to the other side and let it spring back. too much, and you'll bend it the other way. Everytime is springs back just a little bit closer to true. I bent the forward/backward direction first, then then right/left. Using an inexpensive 12 ton hydraulic press:   And here is the result:  I'm inclined to reuse it. What do you think? |

|

|

|

Post by JerryScript on Feb 22, 2015 20:42:34 GMT -5

You seem to know plenty about metal and bending, the one thing that concerns me is the metal has already been stressed, wouldn't that make it easier to deform again?

|

|

|

|

Post by lain on Feb 22, 2015 22:16:19 GMT -5

I would do it. I straightened my tripletree by getting a friend to hold it as I banged on it with a mallet. Have been riding on it since last July. Mine is still a tad bit off but not noticeable really unless I have a heavy passenger lol.

|

|

Freshman Rider

Currently Offline

if God had wanted us to be naked we would have been born that way , Hey wait a minute

Posts: 67  Likes: 14

Joined: Jun 25, 2014 10:04:47 GMT -5

Likes: 14

Joined: Jun 25, 2014 10:04:47 GMT -5

|

Post by nakedguy on Feb 23, 2015 16:44:47 GMT -5

Being a welder /fitter all my life I would not worry about reusing it , if you bent it cold you really have not changed the metal structure, if you heated it you might have made it a little softer or harder depending how you cooled it

|

|

|

|

Post by JerryScript on Feb 23, 2015 23:29:38 GMT -5

Being a welder /fitter all my life I would not worry about reusing it , if you bent it cold you really have not changed the metal structure, if you heated it you might have made it a little softer or harder depending how you cooled it Thanks for the info, always good to hear from someone with years of experience in a particular area!  |

|

|

|

Post by rdhood on Feb 24, 2015 8:08:06 GMT -5

That is what I think to. I think 1) as long as I don't cause a bend in the opposite direction, and 2) as long as I TIGHTEN the steerer bearing properly and don't take another hit with it loose, and 3) as long as there is no damage to the weld holding the steerer tube in the tree itself, everything should be fine. If properly tightened, there should be very little lateral stress on the steerer tube inside the frame. So I am going to put it back on and ride it.

BTW lain, I tried the "bang on it with a mallet", too, and could not get it to budge. That's when I turned to the press. I got it back within 1/16"... shouldn't have any residual problems.

|

|

|

|

Post by rdhood on Feb 26, 2015 17:17:27 GMT -5

Got my new triple tree in and can finally put a micrometer to it... and it is a VERY VERY close fit. the bottom of the steerer is 1mm bigger (old=29mm, new = 30mm), and the top of the steerer where the top bearing goes is .5mm larger in diameter (old = 25mm, new = 25.5mm). Every other measurement is dead on. Even the two nuts that hold it together fit the new triple tree, the threaded section distance from bottom of bearing race , as well as the attachment hole (distance from bottom of bearing race) is dead on. This TT almost a direct replacement.

THAT SAID, it is a one way trip. if I widen the inner diameter of the bearing races by 1mm/.5mm, then I can't use them on the old triple tree. So I am going to put the old straightened triple tree back on, and put the new triple tree in storage. If the old one takes another hit and bends, then I will swap them out.

|

|

|

|

Post by geh3333 on Feb 26, 2015 18:28:42 GMT -5

Got my new triple tree in and can finally put a micrometer to it... and it is a VERY VERY close fit. the bottom of the steerer is 1mm bigger (old=29mm, new = 30mm), and the top of the steerer where the top bearing goes is .5mm larger in diameter (old = 25mm, new = 25.5mm). Every other measurement is dead on. Even the two nuts that hold it together fit the new triple tree, the threaded section distance from bottom of bearing race , as well as the attachment hole (distance from bottom of bearing race) is dead on. This TT almost a direct replacement. THAT SAID, it is a one way trip. if I widen the inner diameter of the bearing races by 1mm/.5mm, then I can't use them on the old triple tree. So I am going to put the old straightened triple tree back on, and put the new triple tree in storage. If the old one takes another hit and bends, then I will swap them out. That's what I would do also . |

|

|

|

Post by rdhood on Mar 1, 2015 1:11:06 GMT -5

Done. Removed the bearings from the smashed cage, picked up a few more at a local bicycle shop to fill in the space, greased top and bottom bearings and reassembled. I had a bit of trouble inserting one of the forks... just didn't want to go, but I managed. It all looks good now:  |

|

|

|

Post by JerryScript on Mar 1, 2015 2:11:32 GMT -5

I don't know, I kinda liked the laid back leaned over look in the first picture, maybe it's just me!  J/K, great job, enjoy the ride!  |

|

|

|

Post by rdhood on Mar 1, 2015 14:02:18 GMT -5

I had a bit of trouble inserting one of the forks... just didn't want to go, but I managed. It finally dawned on me what the deal with the hard to insert fork. If you look where I put the triple tree on the press sideways, pressing closed up the gap in one side of the triple tree. I then put the triple tree back in BEFORE inserting the fork, only to find out that the fork would not insert. "What went wrong?", I thought. I sacrificed a screwdriver opening the gap back up, and even then had to hammer on the bottom of the fork with a rubber mallet to get it to go in. The moral of the story is to make sure that the fork legs go back into the triple tree BEFORE mounting it. |

|

|

|

Post by rdhood on Mar 1, 2015 15:39:24 GMT -5

Took it for a spin, its tracking straight and true with no funky vibration... looks good...

|

|

Sophomore Rider

Currently Offline

Posts: 137

Likes: 24

Joined: Jul 6, 2013 21:27:28 GMT -5

|

Post by mopojo on Mar 2, 2015 12:14:48 GMT -5

Great job. I hate to do it but it still looks a bit off to me.

Hey; just tryin' to pass on a little of my OCD.... LOL

|

|

|

|

Post by rdhood on Mar 2, 2015 17:46:25 GMT -5

Great job. I hate to do it but it still looks a bit off to me. Hey; just tryin' to pass on a little of my OCD.... LOL Optical illusion. If you blow the pic up, put a straight edge on the tire center line, it is spot on with the centerline of the bike. I'm happy with it. I have about ten miles practice just running around the neighborhood and executing tight turns... getting ready for my dmv test. |

|