Currently Offline

Posts: 0

Likes:

Joined: Nov 21, 2024 20:13:51 GMT -5

|

Post by Deleted on Sept 19, 2013 12:28:38 GMT -5

I have yet to break one and i have had mine off many times this way.

|

|

|

|

Post by alleyoop on Sept 19, 2013 12:39:18 GMT -5

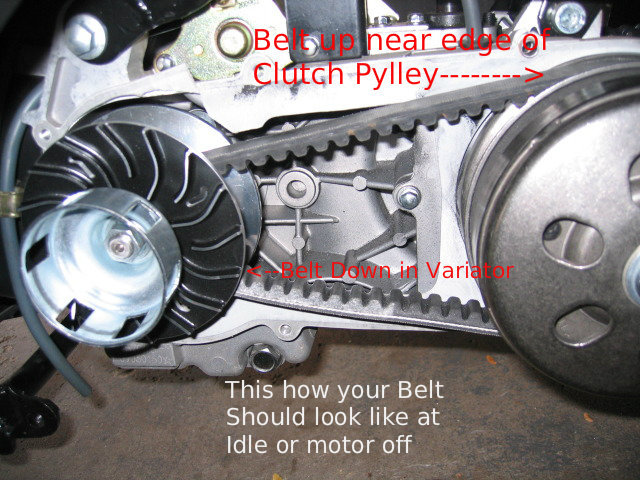

Looking at your picture the weights are sideways in the variator and keeping the variator OUT and not retracting to open the variator to drop the belt down.

So yes Variator has to come off no ifs or buts about it.

They gave you some good ways to take the nut off. If still you can't do it roll it to a garage they will take it off for you. But you will need a new nut, I would suggest order a couple you never know.

Alleyoop

Alleyoop

|

|

New Rider

Currently Offline

Posts: 11

Likes: 0

Joined: Aug 15, 2013 21:10:13 GMT -5

|

Post by zeedhen on Sept 19, 2013 14:08:31 GMT -5

well i gave it a heck of an attempt....the monkey wrench cant get a good enough grip on the rounded nut to wrench it off.....looks like im gonna have to find a garage or someone with better tools than mine....was thinking about taking a dremel to it but im afraid of messing up the threads so ill just let someone else do the work lol

|

|

Sophomore Rider

Currently Offline

Posts: 163

Likes: 15

Joined: Aug 20, 2013 13:54:34 GMT -5

|

Post by phssthpok on Sept 19, 2013 15:10:28 GMT -5

Irwin Bolt Grip (or similar knock-offs) work a champ on rounded nuts/bolts.   There are similar versions with straight 'teeth' that you hammer onto the bolt, but I prefer the kind that *don't* leave the tool attached if you can't break the nut free.

|

|

Sophomore Rider

Currently Offline

Posts: 213

Likes: 4

Joined: Mar 10, 2013 15:08:17 GMT -5

|

Post by crawdad on Sept 19, 2013 16:42:47 GMT -5

Welcome to our Forum! One way or another these guys will get you back on the road . Ive been in a number of Forums over the years, and I have never seen a Forum with so many people with the experience these guys have . Good Luck !!  |

|

Freshman Rider

Currently Offline

Posts: 77

Likes: 1

Joined: Feb 26, 2013 21:10:09 GMT -5

|

Post by rae4180 on Sept 19, 2013 17:26:15 GMT -5

Well you will have to take the VARIATOR off, some of the weights probably CAME out fell out when you took the CVT over off. Also any weights in there are probably laying on there side and not in the ramps correctly. Standing still the belt should be down in the Variator and on top on the Clutch pulley: Alleyoop  is tha a pull start. |

|

Sophomore Rider

Currently Offline

Posts: 211

Likes: 1

Joined: Aug 7, 2013 1:36:49 GMT -5

|

Post by f4milytime on Sept 19, 2013 18:03:24 GMT -5

well i gave it a heck of an attempt....the monkey wrench cant get a good enough grip on the rounded nut to wrench it off.....looks like im gonna have to find a garage or someone with better tools than mine....was thinking about taking a dremel to it but im afraid of messing up the threads so ill just let someone else do the work lol Worst case scenario new crank. If you do mess up the threads I think you can tap -n- dye it, not sure though. |

|

|

|

Post by alleyoop on Sept 19, 2013 19:02:43 GMT -5

Rae1480,

Yes that is a pull start, my trike in Sig came with it.

Alleyoop

|

|

Freshman Rider

Currently Offline

Posts: 77

Likes: 1

Joined: Feb 26, 2013 21:10:09 GMT -5

|

Post by rae4180 on Sept 19, 2013 21:11:57 GMT -5

Rae1480, Yes that is a pull start, my trike in Sig came with it. Alleyoop mmm That gives me a idea for my 50 cc moped. my kick start is broken and I aready have pull start laying around. |

|

|

|

Post by alleyoop on Sept 19, 2013 21:22:05 GMT -5

Rae4180,

If you get the pull start working on your 50, take pictures and write up a how-to and I will move it to the tech section so others may possibly do the same. Since the kickstarts always seem to break.

Alleyoop

|

|

Currently Offline

Posts: 0

Likes:

Joined: Nov 21, 2024 20:13:51 GMT -5

|

Post by Deleted on Sept 23, 2013 20:32:19 GMT -5

I have yet to have that wrench fail me. It works on smooth pipes! How could it not bite? It has no choice but to bite in the direction you pull.

|

|

Freshman Rider

Currently Offline

Posts: 88

Likes: 0

Joined: Mar 4, 2013 23:23:52 GMT -5

|

Post by woowilly on Sept 24, 2013 1:37:36 GMT -5

When using an impact wrench, always use a 6 point impact socket. Regular sockets will split, 12 point sockets will round off the nut or bolt if it's really on tight.

Sometimes I'll use an inch size socket or wrench on a metric fastener ( or vice versa ) if there's one that fits tighter. 13mm is close to 1/2 inch. 14mm is close to 9/16. and there are others.

To get off a rounded off nut, sometimes you can get by by grinding off the entry radius on a 6 point socket, then tapping it fully down with a hammer. Usually it's just the outer half that rounds off due to a loose fitting large entry radius 12 point socket or wrench.

One way I've used to get off rounded off nuts is to grind opposing sides until just barely into the tips of the threads all the way across the nut, then take a chisel to the thicker part of the nut and beat on it in the direction that unscrews it, the nut will spread apart enough to unscrew if it doesn't split in two.

|

|