New Rider

Currently Offline

Posts: 44  Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

|

Post by stellarfoxy on Apr 30, 2015 16:58:20 GMT -5

Hello all! almost a year ago, I acquired a pile of plastic and metal that had apparently been abandoned behind a friends rental property. It was missing the entire intake, exhaust, ignition, various body panels, random nuts and bolts, vacuum/fuel lines, etc. What was left was mostly broken.

Naturally, with no small engine or motorcycle experience whatsoever, I decided I could get it running and have something fun and practical to ride around on. So began the long journey, which was held up a few months by acquiring a title, but that was ultimately a success. hooray!

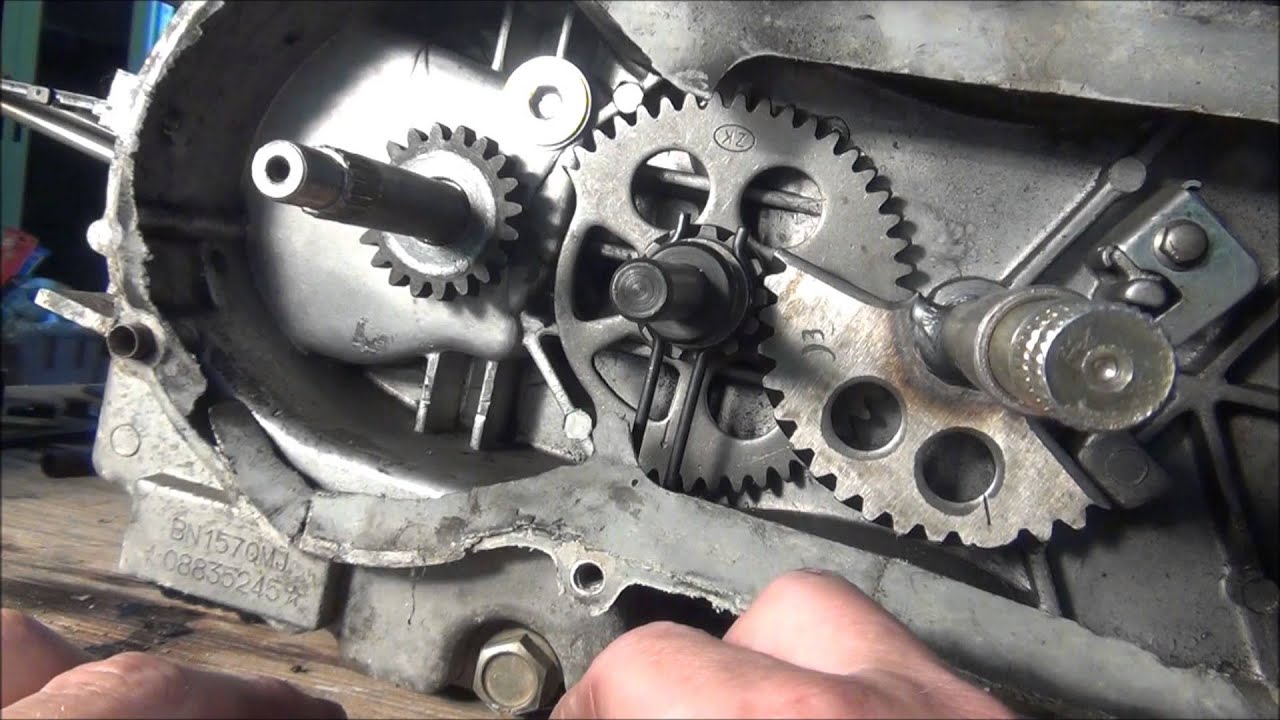

...But this was no ordinary scooter! it turned out to be a cursed powermax 150cc that had been ridden hard for at least 5000 of the 5500 of whatever distance unit the odometer shows and appeared to never have had any maintenance done to it. upon visual inspection, the rear tire had holes in it from burnouts or locking up brakes and virtually every missing part had been removed by force. after replacing damn near everything simple on it (double on some parts, can't be too sure!) and even replacing the timing chain (without removing the head!!), I had come to find out that the cam gear marks refused to line up, and the reason was because the gear on the crank had slipped. how does that even happen, I don't know. unless the previous owner jammed a stick in the exhaust valves while it was running? anyway, I jumped right in and hap-hazardously ripped the whole engine apart to replace the crank. I figured it was easier than trying to realign the gear, and they are only like $50 so what the .

tl;dr, it runs strong now with an A9 cam (whatever that means, it was huge lift compared to stock), uni filter, knockoff keihin carb with 110 jet, dr. scoot rollers, rainbow color straight-thru muffler, orange adjustable cdi, orange coil, new badass fuel and vacuum lines, new piston, new crank, new head, new gaskets all around... I'm way more knowledgeable of this engine than I ever intended to be. any questions about the painful build, lmk. I did gain some interesting cross-referencing info I'll contribute later.

|

|

|

|

Post by shalomdawg on Apr 30, 2015 19:35:42 GMT -5

howdy and welcome. i'm mostly the opposite in that i don't want to do anything to it and when that needs done----sell it or trade it while still running.

some of the people hangin' around will be on shortly to admire your get-to-it-iveness.

lotsa miles and smiles to ya

ken

|

|

|

|

Post by dmartin95 on Apr 30, 2015 19:51:57 GMT -5

Naturally, with no small engine or motorcycle experience whatsoever, I decided I could get it running   That's good stuff right there. ---------------- I do have one question for ya... What did you do to press the kickstarter gear back on? |

|

New Rider

Currently Offline

Posts: 44  Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

|

Post by stellarfoxy on Apr 30, 2015 22:43:54 GMT -5

thanks Ken! there isn't a piece on that engine I haven't laid my grubby hands on at this point. I disassembled the forks tonight and found the seal size, surprisingly difficult to find online- 31x43x10.3 in case anyone was wondering.

dmartin- hello and thanks for appreciating that lol. I never thought it would take so much effort, but once you get so far... why stop now?! as for the kick start gear, I didn't. the mechanism was all jacked up and I didn't feel like kick start was worth it when it takes so much effort to start anyway. the starter has been through trying to start this thing with the timing off, so bad it melted the filter a little. I figure I'll just keep a really close eye on the starter lol

|

|

New Rider

Currently Offline

Posts: 44  Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

|

Post by stellarfoxy on Apr 30, 2015 22:46:44 GMT -5

also, fun fact about the rear axle nut (which was missing, along with the spacer) it's a weird size abd hard to find locally, but the passenger side rear axle nut from a Mazda 323 is the exact same size and.. well, made to take more abuse. plus locally sourceable and cheap.

|

|

|

|

Post by dmartin95 on Apr 30, 2015 23:49:01 GMT -5

dmartin- hello and thanks for appreciating that lol. I never thought it would take so much effort, but once you get so far... why stop now?! as for the kick start gear, I didn't. the mechanism was all jacked up and I didn't feel like kick start was worth it when it takes so much effort to start anyway. the starter has been through trying to start this thing with the timing off, so bad it melted the filter a little. I figure I'll just keep a really close eye on the starter lol Thanks for the reply.... I'm talking about the actual kick starter gear... It's behind your boss and variator.... Not the actual kick start lever and large kick starter gears.... Sorry if I wasn't specific... (I'm talking about the little gear on the crankshaft)  |

|

New Rider

Currently Offline

Posts: 44  Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

|

Post by stellarfoxy on May 1, 2015 16:58:55 GMT -5

What I did was slide the magnetic flywheel on the other side with the woodruff key in place to keep it from turning, held that still with a device ebay describes as a "FlyWheel Clutch Hub Rotor Sprockets Spanner Wrench Holder Adjustable Tool" which prevented the crank from turning, then installed the spacer and variator and cranked down on that nut. I was communicating with a gy6 guru who said that most of them are assembled with impact guns and are extremely over-torqued from the factory, which is why they are difficult to remove, but they don't need that much to stay. Since mine was mostly a spacer I just tightened it up and it worked perfectly.

|

|

|

|

Post by dmartin95 on May 1, 2015 20:22:19 GMT -5

What I did was slide the magnetic flywheel on the other side with the woodruff key in place to keep it from turning, held that still with a device ebay describes as a "FlyWheel Clutch Hub Rotor Sprockets Spanner Wrench Holder Adjustable Tool" which prevented the crank from turning, then installed the spacer and variator and cranked down on that nut. I was communicating with a gy6 guru who said that most of them are assembled with impact guns and are extremely over-torqued from the factory, which is why they are difficult to remove, but they don't need that much to stay. Since mine was mostly a spacer I just tightened it up and it worked perfectly. Thanks Brother! That was exactly the type of info I was looking for. Have a bone on me! |

|

|

|

Post by dmartin95 on May 1, 2015 20:42:55 GMT -5

What I did was slide the magnetic flywheel on the other side with the woodruff key in place to keep it from turning, held that still with a device ebay describes as a "FlyWheel Clutch Hub Rotor Sprockets Spanner Wrench Holder Adjustable Tool" which prevented the crank from turning, then installed the spacer and variator and cranked down on that nut. I was communicating with a gy6 guru who said that most of them are assembled with impact guns and are extremely over-torqued from the factory, which is why they are difficult to remove, but they don't need that much to stay. Since mine was mostly a spacer I just tightened it up and it worked perfectly. The reason I was asking about this is I majorly F'd up..... I thought the kick starter gear had to be pressed on. What I did was put the gear on the crank, then used the boss and a large bolt as a shim to come up past the splines about 3~4mm.. I then got the original nut and put it on the threads... Got a breaker bar on the other side of the crank to hold it in place... Hit the variator side (the variator was not installed for this) with the impact... I hit it too much apparently and stripped the crankshaft thread ends right out... The real kick in nads? In the process I got gear so tight, when I went to remove the kick starter gear, I had to break out the gear puller. |

|

New Rider

Currently Offline

Posts: 44  Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

|

Post by stellarfoxy on May 13, 2015 9:16:23 GMT -5

Apparently that's the exact factory procedure, so at least you've got that? they just have the luxury of hitting those threads the first time so they don't come apart!

did you end up having to replace the crank?

I'm struggling to find fork seals right now. I have a set I got off ebay that are correct size, but in the removal process one of the dust covers got destroyed and I cannot find those anywhere in the US. there's a few available in europe, but next to nothing here. Apparently a 2003 honda cb250 has the same size forks and dust seal, but even that is hard to find parts for. If anyone has any leads on where to find 31mm x 43mm dust seals, hook me up with a link! I can't find em anywhere!!

EDIT: found them. apparently the 31/43 is a strange size. had to order them out of Australia.

|

|

|

|

Post by dmartin95 on May 15, 2015 8:08:56 GMT -5

Apparently that's the exact factory procedure, so at least you've got that? they just have the luxury of hitting those threads the first time so they don't come apart! did you end up having to replace the crank? Yeah, I had to replace the crank. Luckily I had a spare crank on hand and it didn't stop my build but to say I was shocked is an understatement... This was my first time building a GY6 engine, but I've had my tools on everything from lawn mower engine to a Z28 with a Vortec supercharger.... This was a first... Normally the crank is the hardest metal... Forged steel... But it was the crank that stripped, not the nut... O'well, we live, we learn... The crank probably is still usable, just have to re-thread it with the next size down... |

|

New Rider

Currently Offline

Posts: 44  Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

|

Post by stellarfoxy on May 16, 2015 18:35:32 GMT -5

haha I found my tool collection growing from this, the handful of special tools plus I got a hone and gear puller, I don't think I needed anything else? I bought a compression tester just in case also which was helpful. these engines are amazing in their simplicity though, I was surprised at how well thought-out the design is, even though it's apparently around 30 years old? I felt very little hesitation in my decision to just start ripping it all the way apart. everything makes sense on it, everything has a purpose. it's also easy to see which modifications affect the engine and how. I'm completely enamored with the design lol

|

|

New Rider

Currently Offline

Posts: 44  Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

Likes: 10

Joined: Apr 30, 2015 14:48:49 GMT -5

|

Post by stellarfoxy on May 16, 2015 18:38:24 GMT -5

I've done work on a lot of different Japanese cars and a couple of European and American ones, they are all complicated and efficient and start quickly and control emissions and whatever, this engine wants nothing to do with that. it's simple. and it's beautiful for it.

|

|